Progress Report #004 | Visit on 23 March 2023

Progress report on Project CL Navetta 42 #10

Location: Ancona, Italy

Report compiled by Matthew Sainz, Project Manager at Arrow Monaco on 28th March 2023.

Introduction

• Arrow Monaco has been engaged to review the status and quality of build of the new build Custom Line 42m hull number 10.

• The outfitting is taking place at the Custom Line/Ferretti facilities in Ancona.

• The following report illustrates the status of the build as of the 23rd of March 2023 when the vessel was visited.

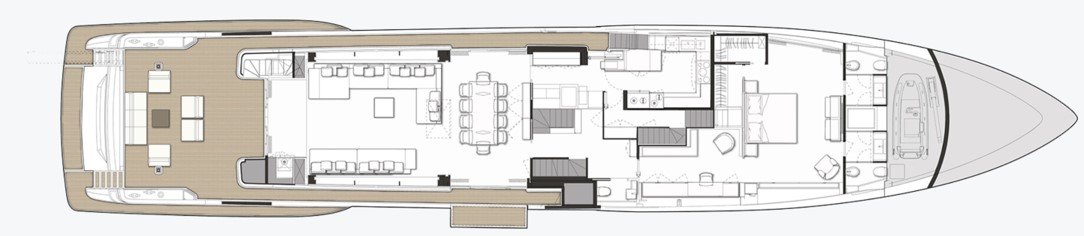

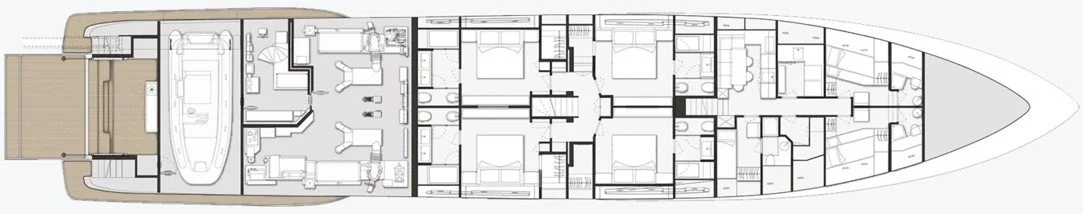

• The finished vessel will have the following arrangement:

01 - Exterior Views

View from aft stbd quarter

•Transom door is now in place, and the piston and full mechanism of hinges are being installed and tested,

•Side garage door has been tested and is now undergoing painting under a temporary shed,

•Rollbar and mast are not at the yard yet,

•Handrailing for all decks has initiated installation, and is mostly complete,

•Outfitting of the aft bar area is in progress,

•Teak decks are in place in many areas,

•Windows are all installed except for the aft lower deck guest cabin on STBD side, this is being used to get the final parts of the cabins into the boat,

•Side fashion plates are on the yard floor and are in the process of being installed,

•Covers/carters for side ladders are being installed.

Stern door now in place and installation being completed

Rudder now in place with shaft line installed

Aft stern thruster installation (missing propeller)

Side ladder covers/carters being installed on both sides. (Notice opening in window for embarkation of internal joinery from there)

Side garage during installation

Cowlings for speed/depth logs being installed.

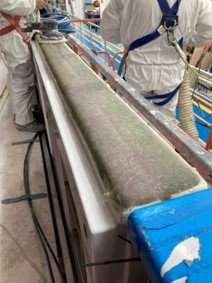

Exhaust cowlings have now been fully laminated to the hull. They are missing the fibreglass cover to be installed little prior to launching.

Master cabin STBD window has now been changed to new. It had previously cracked

Stabilizers mechanism in place (missing the fin which will be installed little prior to launch)

View from bow areas

These area had been taken to an advanced stage of outfitting as described in our last report of December 2022, which is the following:

•Bulbous bow protection strips have been installed,

•Boot stripe has been painted,

•Anchor chain plate has been installed,

•Anchor protection bars have been installed,

•Fairleads are now in place,

•Bulwark hatches for anchor viewing are not in place.

Items to report as in progress and missing to this date are:

•Bulwark hatches for anchor manoeuvring to be installed,

•Antifouling cycle to be applied to underwater hull.

Items which have been completed since the December report:

•The bulwark top handrail has now been installed and can be seen from this view.

Material on the yard plateau

The following components are located under the vessel and readily available to be installed:

•Engine room extractors,

•Bollards and hatches,

•Handrailing,

•Passerelle/gangway.

Material on the yard plateau

The following components are located under the vessel and readily available to be installed:

• Stern door,

• Side garage door,

• Interior pre-cut woodwork for cabins,

Material on the yard plateau (pt2)

•Further joinery material,

•Windows ready for installation,

•Water mist separators,

•External doors and hatches

Material on the yard plateau (pt3)

•Teak pre-assembled decks,

•Fashion plates,

•Side garage door (which has been fitted and tested and now is undergoing final painting),

•Sun deck handrailing.

02 - Exterior Decks

Main deck aft cockpit

•Aft transom stainless steel handrailing is now in place.

•STBD side locker door has now been installed,

•STBD technical locker is being outfitted (hatch and piping)

•Fairing for the deck just aft of the sliding door has started,

•External lights on centerline have been installed,

•STBD side locker door has now been installed and locker is being outfitted (hatch and piping),

•Aft capstans (and respective motors) have been installed,

•Fairing for the deck just aft of the sliding door has started,

•Aft transom stainless steel handrailing is now in place.

Main deck side corridors

•Side embarkation ladders have now been installed (these have been in place for about a month),

•Covers/carters for side embarkation ladders are being installed,

•External lighting is being installed,

•Bulwarks railing is mostly in place,

•Fashion plates are being painted on the yard floor and will soon be fitted.

Main deck side corridors (pt2)

•Outfitting taking place on fwd technical locker of STBD corridor,

•Handrailing and outfitting of PT staircase to fwd areas,

•Fairing and completion of side balconies´ cover/carter.

Forward deck areas and side manoeuvring station

•Teak decks have now been laid on the fwd areas of the yacht,

•Further outfitting has taken place in the rescue boat locker, including the installation of the crane,

•Windows have been installed on the bridge,

•Further outfitting in the chain locker/bosun store has taken place.

Forward deck areas – Anchor chain locker (pt2)

•Manoeuvring/piloting station on STBD side (outfitting/electronics missing),

•Bridge doors have been installed and are being faired/painted,

•Aft sliding doors have been installed,

•Rescue boat/jetski crane has now been installed and the locker outfitting has progressed,

•Bridge windows have been installed together with windscreen wiper motors (blades to be installed at a later date.

Forward deck areas and side manoeuvring station (pt3):

•Chain locker & Bosun Store

•Power pack for rescue boat crane is now in place (we are requesting drip trays for this),

•Switchboards are in place for the various apparatus,

•Bilge alarms and suction are now in place,

•Windlass motor and hawse pipe have now been installed.

Upper deck

•Bulwark haindrailing is now in place for this entire deck,

•Teak has been installed,

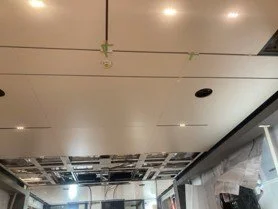

•External ceiling has now been installed,

•Electrical cables have been passed, and central fixed light fixtures have been installed,

•Further outfitting has taken place for the air handler units.

Upper deck (pt2)

•Piping has now been led to their connection points (fire & fresh water),

•External ceiling has now been installed,

•Electrical cable shave been passed, and central fixed light fixtures have been installed,

•Further outfitting has taken place for the air handler units lockers,

•Led lighting strips are now ready for installation under the teak steps.

Sun deck

•Teak decks have now been installed,

•Cabling has been routed into bulwarks for the mast,

•Handrailing and wind screen FWD are being installed.

Sun deck (pt2)

•Nav lights pole in FWD areas is being installed,

•Cabling has been routed into bulwarks for the mast,

•Cabling has been routed for external furniture,

•Handrailing and wind screen FWD are being installed,

•Aft handrailing is now in place,

•Batteries have been installed.

03 - Interior Areas

Main deck lounge

•Works have now moved ahead following the embarkation of the engines and the closure of the hatches on all three decks (main, upper and sun deck),

•Ceilings are mostly in place together with side walls,

•Side and aft sliding doors are now in place,

•AC units have now been installed and most of the ducting for those too,

•Floors have now been closed off, and several finished furniture is now in place.

Main deck lounge (pt2)

•Most final wood work now in place,

•Ceilings installation moving forward,

•AC units in place.

Main deck lobby

•Most final wood work for the staircase down to guest cabins is now in place,

•Ceilings installation moving forward,

•Staircase outfitting in progress.

Master Cabin

•Ceilings have now been installed, and lighting fixtures are being mounted,

•Joinery walls in the finished woodwork are now in place and covered for protection,

•Floors have now been installed,

•Furniture is being installed (FWD cupboards and side furniture).

•A few more images of the Master cabin and the foyer area into the master cabin.

Master Cabin - Bathroom

•Shower basin is resined and ready for outfitting,

•Washbasin furniture is now installed and ready to house the washbasin and faucetry.

•Main joinery walls and furniture are now in place,

•Ceilings have been installed.

Lower deck cabins

•Ceilings have now been installed, and lighting fixtures are being mounted,

•Joinery walls in the finished woodwork are now in place and covered for protection,

•Floors have now been installed,

•Furniture is being installed (Bed furniture, bed side tables, cupboards beneath the TV´s).

Lower deck cabins (pt2)

•A few more images of the guest cabins on lower deck and further furniture which has been installed.

Lower deck cabins (pt2) - bathrooms

•Shower cubicles have outfitted,

•Washbasin furniture is now installed and ready to house the washbasin and faucetry.

•Main joinery walls and furniture are now in place,

•Ceilings have been installed,

•Marble on walls and floors is starting to be installed in the FWD guest cabins.

Galley

•Outfitting of fire protection B15 is complete,

•Outfitting of piping, ducting and cabling close to complete,

•First elements of furniture have been installed and we expect the rest of the galley furniture and apparatus to be installed within the following two weeks.

Bridge areas

•Most of the switchboards are now in place,

•Main console is now in position with some of the instruments and apparatus in their location,

•Main furniture for the radio station and the aft bulkhead are now in place,

•Leather components of the bridge are being installed, and the ceilings (also covered in leather) are being mounted.

Captain´s Cabin

•Ceilings are in place,

•Walls have been installed,

•No furniture is yet present in the cabin,

•Bathroom sees piping being installed and shower cubicles resined.

Upper Deck Aft Lounge

•Works have now moved ahead following the embarkation of the engines and the closure of the hatches on all three decks (main, upper and sun deck),

•Ceilings are mostly in place together with side walls,

•Side and aft sliding doors are now in place,

•AC units have now been installed and most of the ducting for those too,

•Floors have now been closed off, and several finished wood components are now in place.

Crew Areas

•Partitioning is now in place,

•Piping, ducting and electrical cables have now been passed through these areas,

•No furniture is yet installed in these areas.

04 - Technical Spaces

Engine Room & Engine Control Room

•Engine room is at a good stage of outfitting with many components now covered for protection.

•Hamman sewage treatment plant is installed,

•Water makers have been installed,

•Exhaust cowlings are to be installed shortly,

•Alfa Laval fuel purifier has been installed (we are pushing to get a drip tray installed under this).

•Generator have been installed and connected,

•Emergency escape hatch on stbd side is in place (lagging and dbond plating to be completed)

•Batteries are in place.

•Engine control room is mostly outfitted with all its switchboards and piping. Following many weeks of cables laying throughout the area, they have now been connected and the area is looking a little more neat and tidy.

Side Garage

•Much outfitting has taken place in this area,

•The piston for the side door has been installed,

•The sliding hatch into the engine control room is now in place,

•Fuel pistol has been installed on the FWD bulkhead.

CONCLUSIONS

•Progress of the vessel is being monitored on a fortnight basis,

•Outfitting has progressed well particularly in the engine room and engine control room,

•External outfitting is in progress, with installation of the teak decks on many areas, and the installation of deck hardware (handrails, stanchions, wind breakers, etc) having started,

•Most of the windows have been installed except for the stbd aft guest window which is open to allow furniture to be embarked on the vessel,

•Interior areas are progressing well, with lower cabins having a good 80% of furniture installed and bathrooms are just receiving the marble now,

•We have viewed all the bilge areas prior to closure with floors and furniture in guest areas, in order to avoid debris being left under there,

•We have reached an agreement with the yard, that all areas prior to being closed will be witnessed by us,

•We have also reached an agreement regarding the conditions of the underwater hull prior to proceeding with the antifouling cycle. We will be called along for reviewing the status of the hull and the remarks highlighted in the snag list, and will not allow progress until our full satisfaction is achieved,

•Yard has postponed the launch from the 5th of May to the end of May, mainly to get as much work done as possible at the shed, which does help logistics, but also to not have the boat in the water for too long, in view of a delivery in end of October. We will push for even further delay in launching if that were at all possible, however at the moment we cannot foresee any delay in the delivery of the yacht.

•We continue to update the snag list with new items as these are discovered, and closure of items from the yard on our regular visits.