Progress Report #003 | Visit on 7th December 2022

Progress report on Project CL Navetta 42 #10

Location: Ancona, Italy

Report compiled by Matthew Sainz, Project Manager at Arrow Monaco 13/12/2022.

Introduction

• Arrow Monaco has been engaged to review the status and quality of build of the new build Custom Line 42m hull number 10.

• The outfitting is taking place at the Custom Line/Ferretti facilities in Ancona.

• The following report illustrates the status of the build as of the 7th of December 2022 when the vessel was visited.

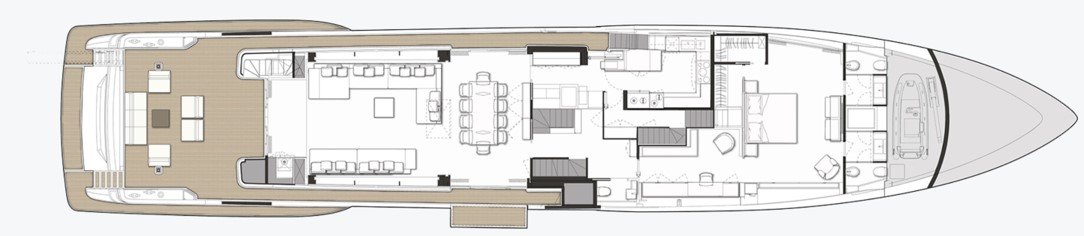

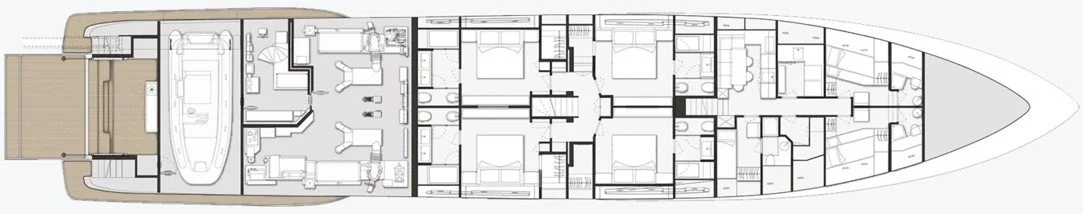

• The finished vessel will have the following arrangement:

01 - Exterior Views

View from aft stbd quarter

• Bootsripe on hull has now been painted,

• Transom door is not in place (viewed on yard floor),

• Side garage door is not in place (viewed on yard floor),

• The mechanism for the side balconies has now been put in place. (Cover and piping yet to be completed)

• Rollbar and mast are still missing (not at the yard),

• Pillars for aft cockpit have been installed,

• Sliding doors for the main deck lounge are now in place,

• Sliding doors for the upper deck lounge are now in place,

• Sliding doors on side superstructure are now installed,

• Interior structure flooring for the garage has now been installed.

Grinding to areas in proximity to shaft bracket

Light grinding taking place for underwater hull

Safety rail for hull windows cleaning in place

(not tested yet)

Mechanism for STBD balcony

(PT side has also arrived)

Broken window on STBD side

(Master Cabin) has been removed

View from bow areas

• Boot stripe has been painted

• Bulbous bow protection strips have been installed,

• Anchor chain plate has been installed,

• Anchor protection bars have been installed,

• Fairleads are now in place,

• Hatch for anchor viewing is not in place,

Anchor Plates and protection bars in place

Bulbous bow protection bars installed

Material on the yard plateau

The following components are located under the vessel and readily available to be installed:

• Stern door,

• Side garage door,

• Interior pre-cut woodwork for cabins,

Material on the yard plateau (pt2)

• Sliding doors components,

• Dampers and grills for ventilation,

• AC units for the cabins and other guest/crew areas,

• Insulation/lagging.

Material on the yard plateau (pt3)

• Cleats and other ground running hardware,

• Shaft line components,

• Bow thruster cover grills and various manholes,

• Engine room ventilators/fans.

Material on the yard plateau (pt4)

• STBD main engine being transported through the shipyard and eventually installed in the engine room passing from the sun deck and lowered into the engine room (passing through all decks)

02 - Exterior Decks

Main deck aft cockpit

• All surfaces are covered with red plastic protection cover.

• Aft capstains and their motors have been installed,

• Fairleads have been installed,

• Pillars on aft areas have been installed,

• Sliding doors into main deck have been installed,

• Wiring for ceiling light fixtures and speakers have been routed.

• STBD technical locker is being outfitted (hatch and piping)

Main deck side corridors

• Side corridor surfaces are protected with red plastic material,

• Windows have been installed,

• Side sliding doors have been installed,

• Pilot door has not been installed yet,

• Fittings on fuel embarkation and water attachments have been installed.

Main deck side corridors (pt2)

• PT side door (access to crew areas) has been installed,

• STBD side technical locker is being outfitted (AHU is now installed and relative ducting/piping),

• Side balconies mechanical components are now in place, pending hydraulic connections and covers,

• Fairleads are now in place.

Forward deck areas and side manoeuvring station

• Manoeuvring station has been covered in red protection plastic,

• The technical spaces in the rescue boat area are being outfitted (fans, piping, ducting, electrical cabling),

• Anchoring station has been installed in fwd areas, including windlasses and eagles claw)

Forward deck areas – Anchor chain locker (pt2)

• Windlass motors have been installed, including hawse pipe for chain to lead into the locker, piping for chain wash and electrical connections,

• Ventilator units and respective ducting has been installed,

• Protection hand railing and flooring has been installed,

• Bulkhead penetrations are in place,

Upper deck

• Stainless steel ladder to Sun deck has now been installed,

• Technical lockers have now initiated outfitting including AHU´s, respective piping and ducting.

• Sliding doors to upper deck lounge has been installed.

• External ceiling is not in place, but located on sun deck.

Upper deck (pt2)

• Stainless steel ladder to Sun deck has now been installed,

• Technical lockers have now initiated outfitting including AHU´s, respective piping and ducting.

• Sliding doors have been installed on aft areas,

• Sliding door on PT side has also been installed.

Sun deck

• Not much outfitting taking place in this area,

• The fibreglass structure we see on top of the deck is the ceiling for the upper deck,

• Support structure and piping/ducting/electrical outfitting is taking place on side areas where components will be routing up to mast/rollbar when this is installed,

• Hard top and mast not seen at the yard.

03 - Interior Areas

Main deck lounge

• Works have been halted in the main deck lounge due to the installation of engines over these few days.

• We assisted to the installation of the STBD engine, whilst the PT in engine had been installed a few days ago.

• The engines are installed through hatches on the main deck, upper deck and sun deck,

• The open hatches on these decks means that outfitting of these areas is halted until the engines imbarkation is not complete,

• With this final embarkation we expect all these hatches to now be closed and outfitting to continue as expected.

Master Cabin

• Ceilings have now been installed,

• Compartimentation walls are in place,

• Raw floors have now been installed.

Lower deck cabins

• Ceilings have now been installed,

• Compartimentation walls are in place,

• Raw floors have now been installed.

Lower deck cabins (pt2)

• Shower cubicles have been sanded and resined,

• Stabilizers have been closed off. Still to be adequately bolted watertight,

• Emergency escape hatch opening has been made, hatch itself yet to be installed,

• Apparatus for watertight doors has been installed and doors are now in place.

Galley

• Outfitting of fire protection B15 is well underway,

• Outfitting of piping, ducting and cabling is underway too,

• The area appears to be awaiting the final finishing to be completed.

Bridge areas

• Several switchboards have now been installed,

• Main console is starting to take shape,

• Ceilings are in place,

• Compartimentation is in place.

04 - Technical Spaces

Engine Room & Engine Control Room

• Engine room could not be visited due to the installation of engines taking place, and thus the area having been closed off for safety/security reasons.

CONCLUSIONS

• Progress of the vessel is being monitored on a fortnight basis,

• There has been a slight run down in resources on board, due to the yard having 3 deliveries in the past few weeks, this has been noticed on the works of joiners in particular, but also piping and electrical subcontractors,

• During our visit on 8th December however we have seen a pick up of works and now with the embarkation of main engines having finished, and hatches on all decks now being closed, we can deduct that works will progress on the 3 areas affected (main deck, upper deck and engine room),

• There have been a series of important embarkations on the boat. Sliding doors, side balconies, windlasses and capstans, engines and generators, have all now been embarked and ready give way for outfitting of respective carters, cabling, piping and ducting from all subcontractors to proceed,

• We will continue to monitor the current chain supply crisis and its repercussions on delivery of critical items on board, however at this stage, and having seen the arrival of some of the finest components (converter, engines, generators) we cannot foresee any delays.