Progress Report #03 | May 2023

30/05/2023

Introduction:

Below is a series of images relating to the works in progress on the Mangusta 104 hull no. 6.

Arrow representatives, Technical Manager Matthew Wood, and Project Manager Harry Noonan have surveyed the build throughout the month of May at the Mangusta facility in Viareggio.

Progress bullet points below :

• Backing plates for intruder trim tabs(Humphreys interceptors) have been resigned in place.

• Pilot holes drilled for underwater lights, and anodes.

• Engine room floor plates, dunnage, and central machinery "island" in place. Will now be removed for paint.

• Anti-condensate paint application underway in the interior.

• Compartmentation finished some resin coating is beginning.

• Cable and pipe runs are loosely run to their locations.

• Scupper pipework insulation is underway as per the request at the specification stages.

• Overboard valves installed for scuppers and some auxiliary systems.

• Sound deadening has been installed in the guest accommodation areas on the waterline to reduce noises.

• Pressure testing of the fire main is underway, and water liquid fill test of the scupper pipework is underway.

• Resin works for the multiplex awning is underway.

• Radar arch and transom door is being manufactured off-site.

STERN – BELOW WATERLINE

Kamewa nozzle gaskets removed for further filling /fairing works on Hull. They will be re set in place later in build.

STERN - BELOW WATERLINE

Below: unpainted section( in white) is in readiness for eventual instal of impellor shaft.

Right: underside of swimming platform.

HULL

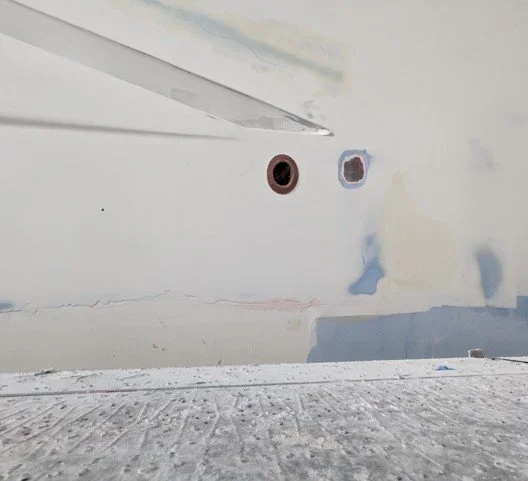

Below: Drill holes for fin and Main engine exhaust starboard side.

Right: scupper drain outlets.

HULL BOW AREA

Right: close-up of bow thruster blades, grinding work ongoing.

Below: Anchor plate area awaiting stainless steel fittings.

STERN/TRANSOM

Right: View of garage from aft of the vessel.

Below: Fibreglass awning pole inserts being measured correctly.

ENGINE ROOM

Below: engine room auxiliary overboard valves installed.

Right: further plate work and ER blower boxes.

ENGINE ROOM CONT.

ER as viewed from crew mess. Advancement in framework and introduction of fitted checker plates evident.

ER structural FRP exhaust network.

MAIN SALON

Below: Main salon as viewed from forward near wheelhouse.

Right: Main salon as viewed from aft.

MAIN SALON CONT.

Below: scupper drains and locker drain installations.

Right: Awning drainpipes.

SIDE DECK

Below: Continued filling and fairing of access hatches/lockers/fittings.

Right: scupper liquid fill test in operation.

FOREDECK

Below: pressure test evident on fire main.

Right: GRP insert for awning poles. These areas are reinforced to withhold incredible strain. Well designed.

FLYBRIDGE

Below: Forward view of skylight and foredeck.

Right: Looking aft.

VIP CABIN / GUEST AREA

Bilge areas under guest Cabins recent installations.

Below: Black water manifold/pipe work.

Right: Fresh water manifolds.

Below: sound dampening material installed at water level. This will prevent guests from being disturbed by lapping water.

Right: Interior partition work in marine plywood.

CREW AREA

Below: Hot and cold-water piping in place.

Right: tradesman working on wiring.

OWNER’S CABIN

Cable trays, wiring and insulation stage.