Progress Report | Q1 2023

STATUS REPORT OF VISIT ON 24th MARCH 2023

INTRODUCTION

• Arrow Monaco has been engaged to review the status and quality of build of the new-build Custom Line 140 hull number 3.

• The outfitting is taking place at the Custom Line/Ferretti facilities in Ancona.

• The following report illustrates the status of the build as of the 24th of March 2023 when the vessel was visited.

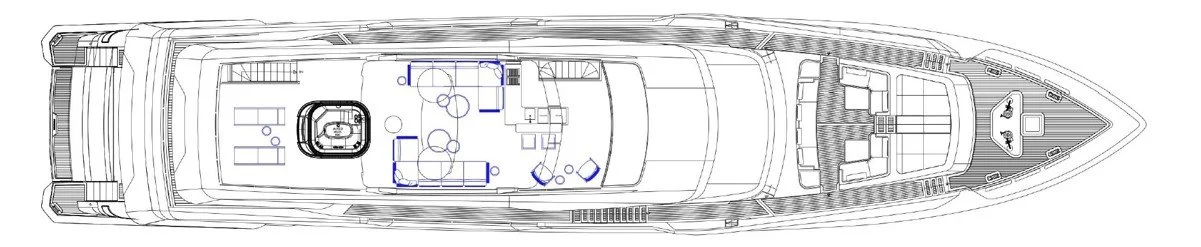

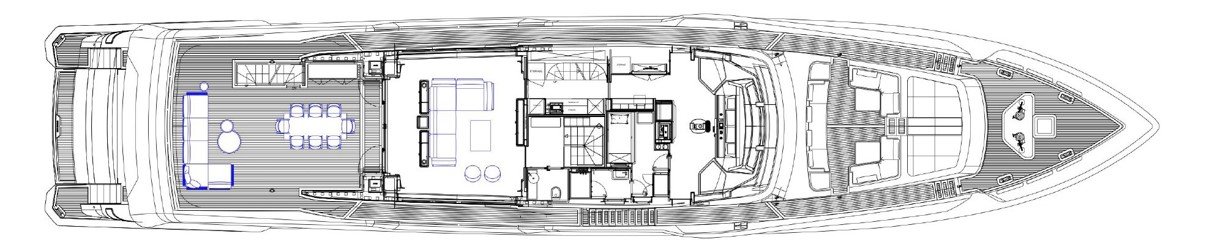

• The finished vessel will have the following arrangement and technical details:

01 EXTERIOR VIEWS

VIEW AFT PORT QUARTER

• Black components of superstructure have now been painted as per the standard colour coding of the vessel,

• Stern thruster hardware has been installed on the transom,

• Intruder system has been installed on the lower transom areas,

• Main deck cockpit pillars are now in place,

• Stern door hardware is being installed,

• Side garage door hardaware is being installed,

• Overboard discharges have been mostly mounted,

• Gelcoat external surfaces generally in good shiny conditions. Some touch ups required and being worked at,

• Glass windows have been installed on main deck,

• External ceilings are now in place,

• Works are taking place in the aft bar area inside the aft transom,

• Rollbar and mast are missing (not at the yard),

• Pilot doors on side bulwarks have not been installed yet.

UNDERWATER HULL - AFT SECTIONS

• Stern thruster hardware has been installed on the transom,

• Shaft line (excluding propellers) has been installed (yet to be fully aligned),

• Rudder stock and hardware has not been installed yet,

• Exhaust cowling carter has been installed on STBD side (not on PT side yet),

• Interceptor trim system is being installed.

UNDERWATER HULL - FORWARD SECTIONS

• Housings for hull sensors have been installed,

• Antifouling cycle to underwater hull has not yet been applied,

• Stabilizer shaft has been installed,

• Bow thruster has been mounted,

• STBD exhaust cowling is undergoing installation, and overboard discharges are in place.

VIEW FROM FORWARD PORT QUARTER

• Windows on the hull and topsides are being installed,

• Portholes are also being installed.

TOP SIDES

• Portholes have been installed,

• Anchor chain plate on STBD side was being installed,

• Side garage door is open for access to garage and engine room,

• Windows on the STBD side have been installed on hull, whereas they are undergoing installation on the superstructure and Master cabin.

MATERIAL ON THE YARD PLATEAU

The following material is stored under the vessel for installation shortly:

• Staircase to Sun deck,

• Side pilot doors,

• Exhaust chambers for generators,

• Stern transom door,

• Rudders.

• Sliding door hardware,

• Stern door hinges and lugs,

• Cleats and rollers,

• Hydraulic power pack for transom door,

• Batteries.

• Fire dampers,

• AC units/Fancoils (yet to be installed),

• Various hardware for piping installations,

• Electrical cables ready for installation.

02 EXTERIOR DECKS

MAIN DECK AFT COCKPIT

• Stern areas next to the sliding doors have been prepared for final coat of painting,

• Pillars are now in place,

• No further progress is noticeable in this area.

A few more images of this area:

MAIN DECK SIDE CORRIDORS

• Windows are undergoing installation in these areas,

• Side doors into crew areas on PT side and Guest areas on STBD areas have been installed,

• The superstructure sides are now ready for the final hand of topcoat,

• Piping installations and respective pressure testing is being undertaken.

A few more images of these corridor areas:

FORWARD DECK AREAS

• Rescue tender crane has been installed on it´s basement,

• Cleats have been installed in fwd manoeuvring areas,

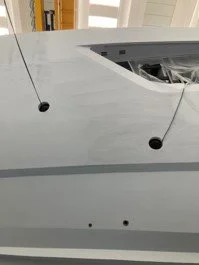

• Yard is getting ready to produce the openings for the windlass manoeuvring station, having positioned the template in it´s correct position,

• Electrical cables have been routed in the rescue tender locker.

A few more images of this area:

• Bridge/wheelhouse doors have been installed,

• Cleats on decks have been installed,

• Side superstructure doors have been installed,

• Crane for rescue boat has been installed,

• Bridge windows are now in place and nearing completion.

• Template for windlass area outfitting now in place,

• Hatch down to technical locker has been installed and glassed into place,

• Details of hatches and recesses for storage and life rings,

• Recess for fire hydrant and fresh water deck points.

UPPER DECK AFT

General views of the upper deck aft cockpit.

• Side decorative windows have been installed,

• Fire hydrant has now been installed in its recess,

• Openings in ceiling for ventilation are visible,

• Interior areas have started outfitting,

• The interior and exterior surfaces of the superstructure have been painted black,

• The opening in the deck for embarkation of the main engines is still visible.

SUN DECK

General views of the sun deck:

• The opening in the deck for embarkation of the main engines is still visible,

• Forward wind breaker is undergoing installation,

• The staircase to sun deck has not been installed yet (seen on the yard plateau),

• Side hatch down to upper deck has been installed,

• Basement structure for the FWD mast is undergoing outfitting.

AFT SWIMMING PLATFORM

This area was open for works and thus could not be inspected in detail during our visit.

03 INTERIOR AREAS

MAIN DECK LOUNGE

• The deck opening hatches for engines embarkation have now been closed,

• The deck floors are being aligned and soon to be installed,

• Insulation is being applied to the side walls,

• Side ducting for engine room ventilation is now in place (and insulated),

• First steps of outfitting for piping, ducting and electrical cabling is moving ahead.

• Piping in aft areas of the main deck lounge,

• Fwd areas show wood raw panels being installed on floor areas,

• Cabling can be seen in top areas,

• Supporting structure for wood ceilings is in place.

MASTER CABIN

• Raw partitioning is now in place,

• Ceiling structure has now been installed ready for the final panels to be installed shortly,

• Raw floors have now been installed,

• Division between cabin and bathroom is now in place,

• Windows are being installed.

A few more images of the master cabin.

MASTER CABIN - BATHROOM

A few images of the state of the bathrooms in the master cabin.

LOWER DECK GUEST CABINS

• Raw partitioning is now in place,

• Ceiling structure has now been installed ready for the final panels to be installed shortly,

• Raw floors have now been installed,

• Division between cabin and bathroom is now in place,

• Windows have been installed.

• Details of some of the furniture which has now been installed,

• Details of the ceiling finished colours,

• Portholes and windows have been installed.

LOWER DECK CABINS - BATHROOMS

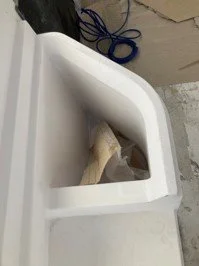

• Shower cubicles have been resined,

• Piping and hardware has been installed for the shower mixer,

• Portholes and windows are installed.

GALLEY

• Pins and insulation have been insulated in the galley, which will provide the required B15 insulation that is required for class,

• Raw partitioning walls have been installed above the insulation,

• Ducting is now in place,

• Ceilings have been installed.

MAIN DECK PANTRY

• Cabling has been routed, but yet to be connected to it´s respective switchboard or apparatus,

• Side hinged door has just recently been installed and does need to be completed.

BRIDGE AREAS

• Windows have been installed,

• Raw bulkhead separations have been installed,

• Recess for exterior storage have been installed,

• Cabling has been routed to these areas, but yet to be connected to switchboards ot panels/apparatus,

• Insulation has now been undertaken and the raw wood ceilings are starting to be installed.

• Side doors have been installed,

• Windscreen motors have been installed,

• Several further views of the bridge areas.

CREW AREAS

• Pins and insulation have been installed on side shell

• Piping has been routed through these areas,

• Electrical cabling has been routed through these areas and waiting for switchboards,

• Furniture is starting to be installed,

• Bathroom furniture is being positioned in its place,

• Showers have been resined and are ready for further outfitting.

04 TECHNICAL SPACES

ENGINE ROOM

• Insulation is now complete in bulkheads, ceilings and side shell,

• Supporting structure for Dbond laminate is now being installed,

• Main engines, gearboxes and silencers are now in place,

• Generators are in place and have been covered for protection,

• Access doors, hatches and staircases are in place.

• Silencers are only missing the cowling to connect it to the overboard discharge,

• Manifolds are in place,

• Overboard discharge sea water coolant (spray rail) is in place,

• Engine room extractors have now been installed,

• Staircase to main deck is in place,

• Hatch on STBD side and into garage is in place.

ENGINE CONTROL ROOM

• Emergency bilge pump has been installed,

• Much cabling has been routed to these areas waiting for switchboards to be installed, and hence cabling can undergo final connections,

• Staircase to main deck is in place on STBD side.

MAIN TENDER GARAGE

• Tender winch has been installed,

• Fuel pump (for tender filling) has been installed,

• Electrical cabling for future connections to switchboards have been routed to this area,

• Supporting structure for ceilings and walls is now in place.

STERN TECHNICAL SPACES

• Piping has been routed in these areas,

• Pumps and hydraulic power packs have been mounted,

• We have complained about the dirty status of these areas. Will be monitoring for improvement.

CONCLUSIONS

• We are keeping an eye on progress on a fortnight basis,

• Smartsheets is being used to monitor the remarks we discover. We are insisting on yard to close off items as soon as possible prior to further outfitting taking place,

• Exterior areas outfitting is in progress and pacing up, with windows being installed and fwd crane. Still quite a lot to be done however, including teak dekcs, handrailing, staircases, hatches doors, windlasses, sliding doors, and many others.

• Exterior hull areas are being outfitted at a good pace, including thrusters, intruders, shaft line and anchor plates in progress. Above line, we see windows being installed at lower deck level and superstructure aft,

• Engine room and technical areas have seen the insulation completed, main engines embarked, and hence the hatches on main deck closed up in order to allow adequate outfitting of the main deck interiors. Dbond plating for the engine room has not initiated. Having said this, the hatches on the upper deck and sun deck (to allow engine embarkation). This should be done at soonest in order to proceed with the outfitting of interior areas in the upper deck lounge.

• Interior are coming along quite nicely, with lower decks having reached a good stage of outfitting, Much to be still done on main deck and upper deck.

• Installation of windows is taking place, but sliding doors have not yet arrived at the yard,

• The roll bar and mast have not yet arrived for installation on top of the sun deck,

• As this moment in time we do not envisage any critical items which could lead to any delays in delivery, and having spoken with the vessel project manager, at the moment the launch is still programmed for end of July.

• With a delivery as per contract established at end of December, we do retain this is plenty of time to undertake sea trials, dock trials and the adequate protocol of delivery. Should we be asked, we would probably suggest they launch the boat later than this, in order to have her under the shed as much as possible and make the most of the better logistics and protection.