Progress Report #003 | Q2 2023

Progress report on Project Custom Line 120 #10

Location: Ancona, Italy

Report compiled by Matthew Sainz, Project Manager at Arrow Monaco 29/06/2023

Introduction

•Arrow Monaco has been engaged to review the status and quality of build of the new build Custom Line 120´ hull number 10.

•The outfitting is taking place at the Custom Line/Ferretti facilities in Ancona.

•The following report illustrates the status of the build as of the 13th of June 2023 when the vessel was visited.

•The finished vessel will have the following arrangement:

• And the following technical specifications:

01 - Exterior Views

View from aft stbd quarter

•Underwater hull is covered and protected for the next steps in the primer and antifouling cycles,

•Pilot door has now been installed,

•Aft fairleads have now been installed (yet to be completed),

•Transom stainless and glass handrailing is now in place,

•Superstructure sides on main deck have now been painted black,

•Top brow has been painted in the metallic dark grey as per the vessel colour plan,

•Installation of the main deck aft lifting door was taking place during our visit,

•Side nav lights are now in place,

•Aft cleats and capstans are now in place,

•External staircase from main deck to flybridge have now been installed.

View from yard plateau (aft areas)

The vessel is covered with plastic protection cover for the antifouling cycle; thus the hull was visited under this protection plastic:

•Apparatus on stern transom have now bene installed,

•Stern door is yet to be installed

View from aft stbd quarter (pt2)

•Swimming platform bracket has been installed,

•Propellers and their relative zinc anodes have been installed,

•Main exhaust cowling on the transom has now been installed,

•Stern thruster hardware is now in place,

•Rudders and intruder system are now in place.

View from bow areas

•Anchor plates are now in place,

•Windows are in the process of being siliconed,

•FWD areas handrailing is now installed,

•Window cleaning Harken rails are now in place.

View from aft stbd quarter (pt2)

•Earthing plates have been installed,

•All overboard hardware has been installed,

•Anchor plates are in place,

•Fin stabilizer thru´ hull has been installed.

Material on the yard plateau

The following components are located under the vessel and readily available to be installed:

•Engine room extractor/ventilators,

•Staircase to upper deck,

•Firefighting cupboard,

•Tanks and panels,

•Stern door.

02 - Exterior Decks

Main deck aft cockpit

•Outfitting is progressing in the main deck aft cockpit areas,

•The flip-up stern door is being installed,

•The aft glass and stainless-steel feature is now in place,

•The staircase to the flybridge is now in place,

•Stainless steel door to swim platform is installed

•Hatches to swimming platform are now in place,

•Stern manoeuvring station and it´s cover are now installed,

•Staircase to flybridge is now in place,

•The aft glass and stainless-steel feature is now in place,

•The stern door was being installed during our visit.

Main deck side corridors

•General outfitting on the side corridors is taking place,

•The sides have been sprayed black as per the colour code of the vessel.

•Access doors have now been installed,

•Pilot doors have been installed,

•Fwd corridor areas have been painted black,

•Final siliconing is taking place on side windows.

Flybridge

•The hatch for the main engine's embarkation is still open on this deck,

•Flybridge sides have now been painted black as per yacht colour plan.

Forward deck areas

•No significant works can be reported in this area,

•Recess locker for rescue tender or fwd jetski are visible,

•Recesses and housing for sunbathing areas are visible,

•Side corridors have been painted,

•Hatches are being installed,

•Windscreen wipers hardware is being installed,

•Openings on fibreglass for controllers and lights are underway (we are requesting these to be capped).

Aft swimming platform and tender garage

•There is substantial progress in the swimming platform, this is open for outfitting of interior garage areas.

•Cleats have been installed,

•The door itself is being installed, including all lugs and piston mechanisms.

03 - Interior Areas

Main deck lounge

•Joinery partitioning floors, walls and ceilings are being installed,

•Cable trays have now been closed off on floor areas,

•Hatch for main engines embarkation has now been closed in order to proceed with outfitting of this area.

Master Cabin

•Joinery is being installed in these areas and in particular around the windows,

•Ducting has been routed through the cabin,

•Floors and ceilings (raw partitioning) is now in place,

•Partition joinery walls have been installed,

Master Cabin - Bathroom

Details of the bathroom areas of the Master cabin

Galley

•Raw wood partitioning is now in place,

•Windows and porthole for the galley are now installed,

•All ducting and dampers have now been installed.

Bridge (Raised Pilot House)

•Much outfitting has taken place here including raw wood partitioning and the console formation,

•Staircase is now in place for access from the main deck.

A few more details of the bridge installation.

Lower deck guest cabins

•Final lacquered ceilings are now in place,

•Several finished panels have now been insalled,

•Windows and respective portholes are now in place

•Floors have now been closed off (having inspected for cleanliness beneath)

Further utfitting details of the lower deck guest cabins

Lower deck Crew areas

•Staircase is now in place,

•Portholes have now been opened up on the hull,

•Piping is starting to be routed through these areas.

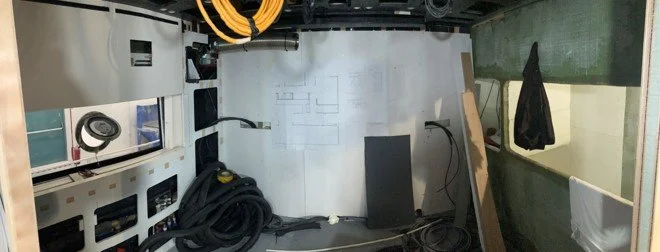

04 - Technical Spaces

Engine Room

Much outfitting has now taken place in the engine room including:

•Main engines and gear boxes installed,

•Generators installed,

•Exhaust cowlings installed,

•Engine room insulation now in place,

•Doors and hatches installed.

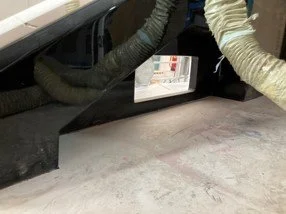

Engine control room / Technical Spaces aft

Main tender garage

•Rollers have been installed,

•Ceiling raw partitioning has been installed,

•Cabling has bene routed here,

•Winch has been installed,

•Ceiling crane has been installed.

CONCLUSION

•Painting of the black waterline fascia is in progress,

•The various dark grey and black details throughout the superstructure have now been completed,

•External decks outfitting is taking place, with cleats, capstans and fairleads having been installed,

•Handrailing and stanchions are being installed,

•Works are also proceeding with the interiors, the lower deck is at a good stage, and partitioning is being completed in the main deck lounge and master cabin,

•Cable trays on floors and the engine room hatch have now been closed off, allowing further outfitting to take place in these areas,

•Engine room and aft technical spaces have moved along swiftly in terms of outfitting with all major apparatus having been installed prior to the deck hatch being closed,

•At the moment we do retain the launch in September and the Delivery for the end of the year to be feasible. At this moment in time we do not see reasons for a delay.