Progress Report #002 | Q1 2023

Progress report on Project Custom Line 120 #10

Location: Ancona, Italy

Report compiled by Matthew Sainz, Project Manager at Arrow Monaco 29/03/2023

Introduction

•Arrow Monaco has been engaged to review the status and quality of build of the new build Custom Line 120´ hull number 10.

•The outfitting is taking place at the Custom Line/Ferretti facilities in Ancona.

•The following report illustrates the status of the build as of the 24th of March 2023 when the vessel was visited.

•The finished vessel will have the following arrangement:

• And the following technical specifications:

01 - Exterior Views

View from aft stbd quarter

•Safety precautions in place (as per safety document present at the yard),

•Electricity, compressed air and extraction are all now adequately routed through the boat,

•Access ladders and passerelles are now providing adequate access to the vessel,

•Transom door is not in place (viewed on yard floor),

•Main engine exhaust cowlings have now been closed off on the lower sides,

•Side pilot doors are not in place (both sides),

•Rollbar and mast are missing (not at the yard),

•Gelcoat external surfaces generally in good polished conditions. Some touch ups required.

•Various of the larger components and apparatus which are to be installed on the yacht are found beneath the vessel, ready for installation,

•Hull is being prepared for the final cycle of antifouling which should take place in proximity to the launch

View from yard plateau (aft areas)

Hull outfitting has moved ahead including:

•Overboard discharges have been capped and hardware installed,

•Exhaust cowlings have now been closed off, leading exhaust fumes all the way aft and out on the transom,

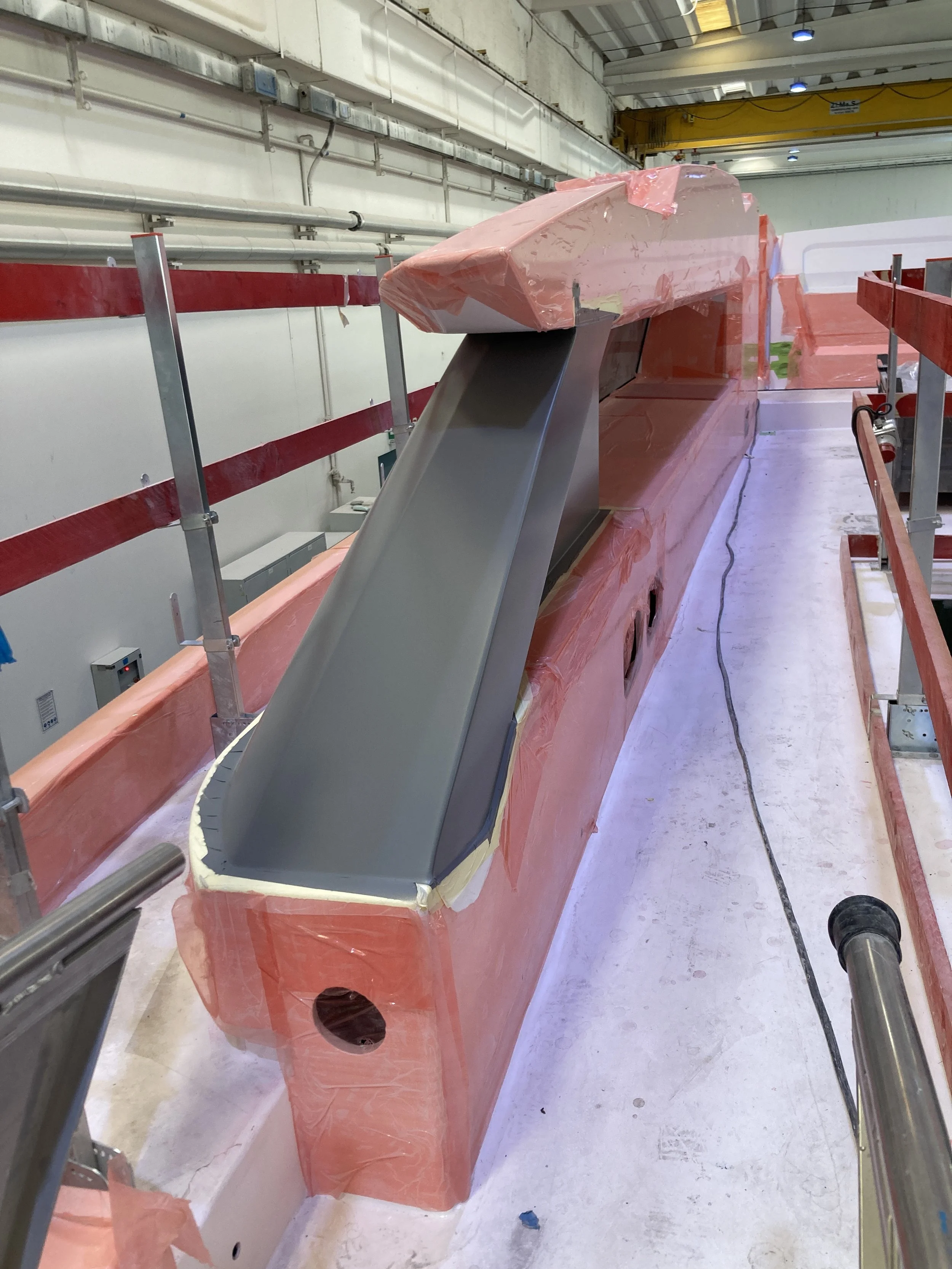

View from aft stbd quarter (pt2)

•Swimming platform bracket is undergoing installation,

•Shaft line is now in place with a pre-allignemnt of the shaft,

•Intruder dynamic trimming system has been installed on the transom,

•Underwater lights are now in place,

•Sea water pick up sea cocks have mostly been installed.

View from bow areas

•Windows on hull have been installed,

•Windows on first tier of superstructure (Master cabin), have been installed,

•Windows on aft lounge have been installed,

•Bridge windows and aft flybrudge are in place.

View from aft stbd quarter (pt2)

•Bow thruster hardware and propellers have been installed,

•Stabilizer cut-outs are visible, and awaiting installation of the stabilizer hardware,

•Underwater sensors have been installed,

•Anchor chains and fwd fairleads are missing,

•Underwater hull will have the full cycle of antifouling applied at a later stage.

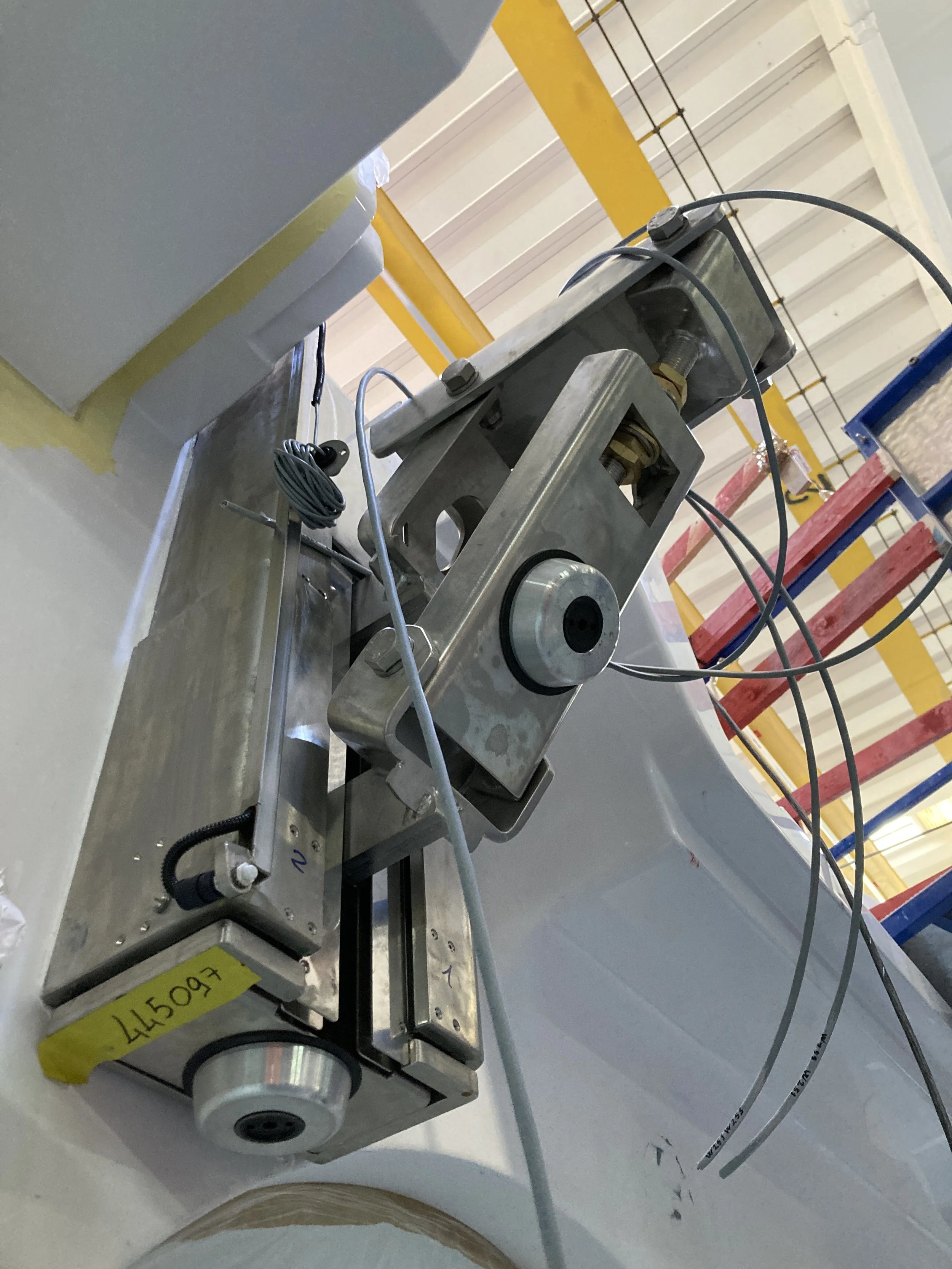

Material on the yard plateau

The following components are located under the vessel and readily available to be installed:

•Bow/Stern thruster apparatus,

•Stern thruster propeller and pod,

•Stainless steel staircases and various handrailing,

•FWD tender/jet ski deployment crane,

•Fin stabilizers,

•Watertight hatches,

•Power pack for gangway unit,

•Fire damper for engine room ventilation/extraction,

•Electrical cabling rolls,

•Cleats and fairleads,

•Power pack for transom door,

•Vertical doors,

•Various hydraulic/piping hardware,

•Toilet units,

•Joinery supporting structure.

02 - Exterior Decks

Main deck aft cockpit

•Not much outfitting is yet happening on aft decks as can be seen form these photos,

•Protection bars for open side walks, and staircases for access to various decks have been installed.

•Double cleats have been installed in the side mooring stations,

•Capstans are also in place, with the foot controls also having been installed,

•A temporary ladder allows access to the flybridge, the stainless steel ladder has been viewed in storage under the boat,.

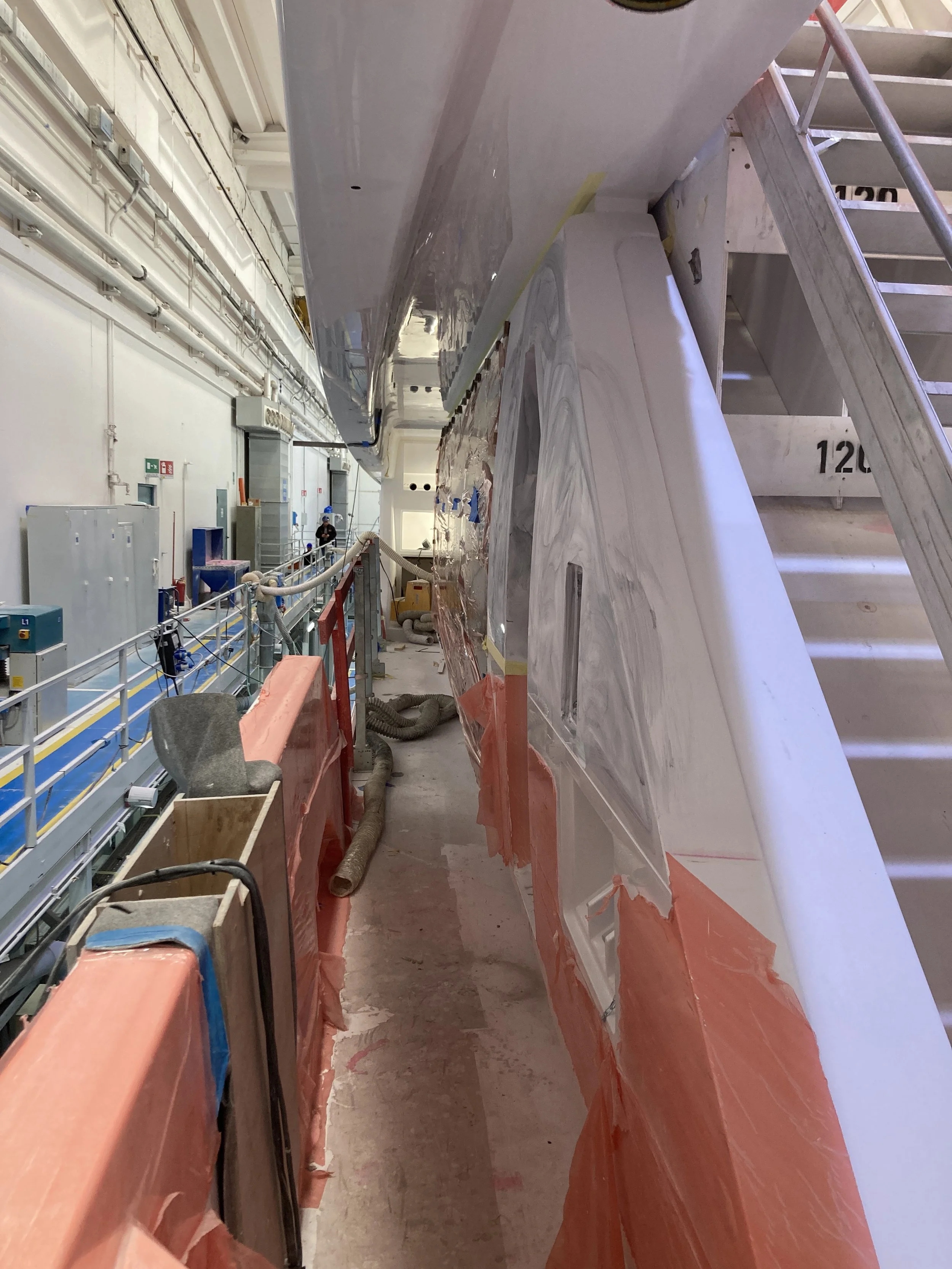

Main deck side corridors

•Side windows have now been installed,

•Outfitting of fire hydrant and other connections has started in the superstructure recesses,

•Pilot doors are not in place,

•Storage furniture in port corridor has started and advancing towards completion,

•Recess for life rings is in place,

•Fairleads are yet to be installed.

Flybridge

•The hatch for the main engines embarkation is still open on this deck.

•Windows have been installed on the superstructure sides,

•Paint preparation has started of the side components.

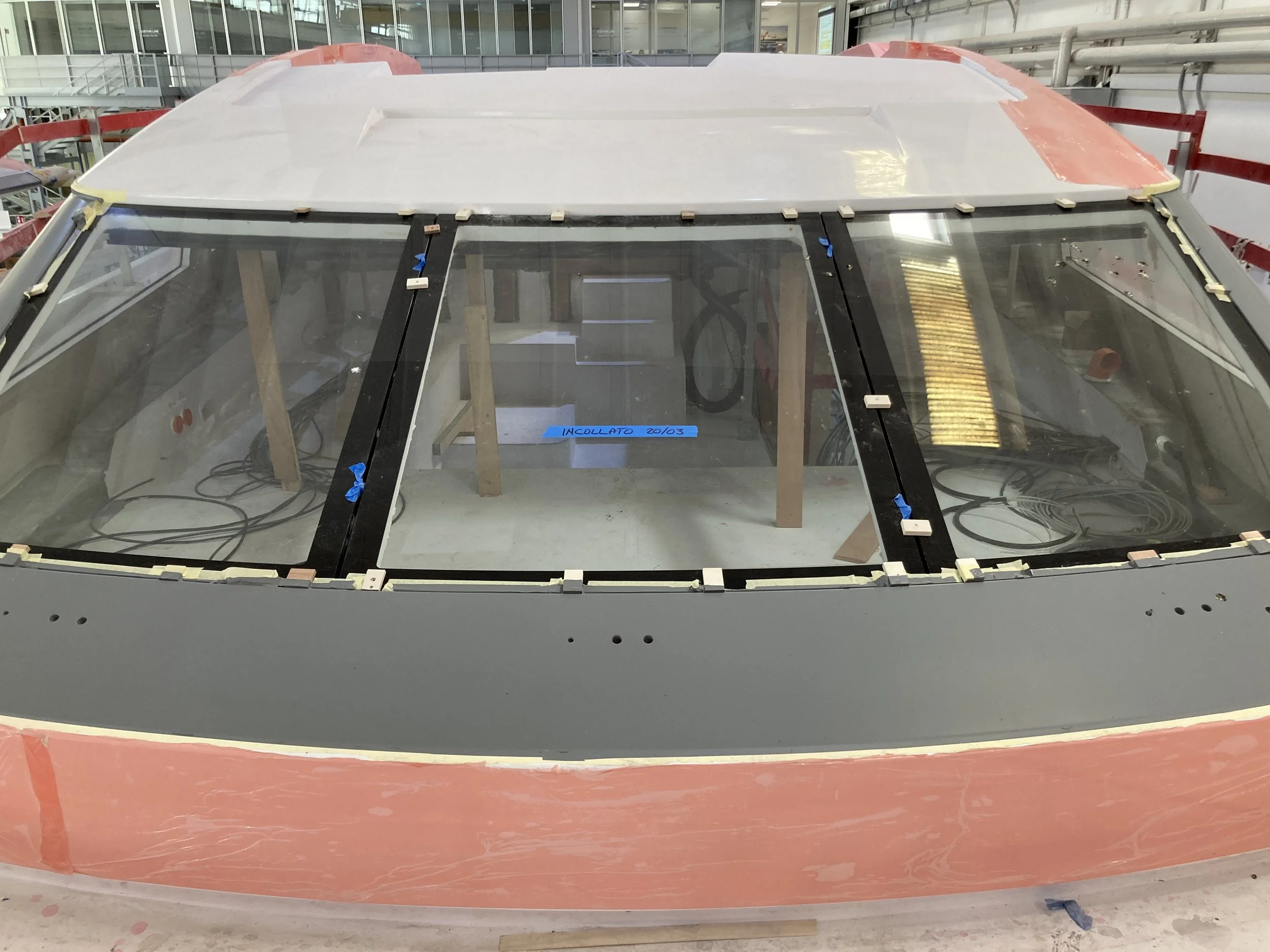

Forward deck areas

•No significant works can be reported in this area,

•Recess locker for rescue tender or fwd jetski are visible,

•Recesses and housing for sunbathing areas are visible,

•Bridge external surfaces are now in preparation for the final coat of topcoat,

•Windlass hardware has been installed,

•Bolting has been drafted for installation of the deployment crane,

•Bridge windows have been installed,

•Openings for window wipers have been made.

Aft swimming platform and tender garage

There is no substantial progress in the swimming platform, this is open for outfitting of interior garage areas

03 - Interior Areas

Main deck lounge

•Electrical cabling has proceeded in these areas in particular to pass the main cables which connect the engine room to the bridge,

•Insulation has been installed on the walls and ceilings,

•Supporting structure for the raw joinery partitioning and ceilings is now in place,

•Piping and ducting have progressed in these areas

A few more details of electrical cabling, piping, ducting and insulation in the main deck lounge

Master Cabin

•Electrical cabling has proceeded in these areas in particular to pass the main cables which connect the engine room to the bridge,

•Insulation has been installed on the walls and ceilings,

•Supporting structure for the raw joinery partitioning and ceilings is now in place,

•Piping and ducting have progressed in these areas.

A few more details of electrical cabling, piping, ducting and insulation in the main deck lounge.

Master Cabin - Bathroom

Details of the bathroom areas of the Master cabin

Galley

•Windows have been installed with respective porthole,

•Ducting has been routed through this space into the technical locker just behind the galley,

•Supporting structure for the raw joinery partitioning and ceilings is now in place,

•Piping and ducting have progressed in these areas,

•Ducting and pipe penetrations,

•Escape hatch into master corridor,

•Ducting routed through the galley,

•Supporting structure for joinery ceilings.

Bridge (Raised Pilot House)

•Raw wood ceilings have started installation,

•Electrical cabling has been routed into these areas,

•Windows installation closes the area off.

A few more details of the bridge installation.

Lower deck guest cabins

Lower decks have progressed the most over these past weeks:

•Window perimeter supporting structure has been installed,

•Wood raw ceilings are now in place,

•Partitioning is installed.

•Piping has been installed,

•Ducting is being mounted and connected,

•Bow thurster cofferdam is temporarily protected, but will be given a second coating of gelcoating prior to delivery,

Lower deck Crew areas

•Staircase is now in place,

•Portholes have now been opened up on the hull,

•Piping is starting to be routed through these areas.

04 - Technical Spaces

Engine Room

•Flooring structure has been installed (and covered with wood ply),

•Ventilation system including dampers are being installed,

•Insulation is proceeding,

•Piping is being routed as well as electrical cabling.

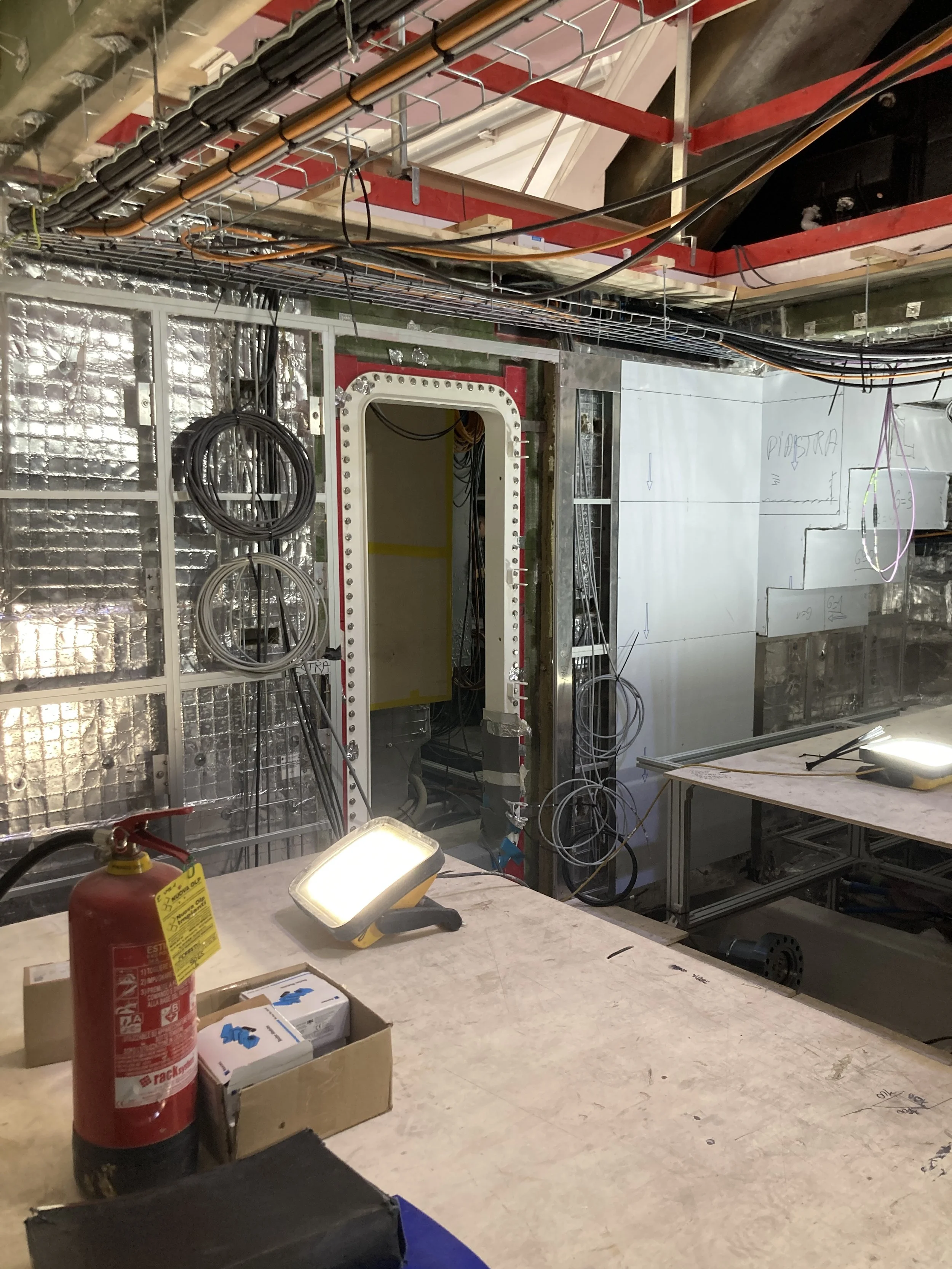

Engine control room

Main tender garage

CONCLUSION

•Outfitting is now moving along at a decent pace, having organised the vessel in it´s final outfitting position, electricity is on board and safety precautions are in place,

•Work is proceeding at a good pace on the underwater hull,

•Windows for hull and superstructure are being installed,

•Works are progressing on internal areas with lower decks (guest and crew) proceeding swiftly and from there upwards,

•Long range electrical cabling and piping is still being routed throughout the vessel,

•Engine room and aft technical spaces are moving along well,

•External decks see minor progress, rollbar and mast are not yet present at the yard,

•Having spoken with Lorenzo our PM, we do expect a launch of the vessel in September. The contractual delivery is established for the end of the year. At this moment in time we do not see reasons for delay.