Progress Report #001 | 08 Dec 2022

Progress report on Project Custom Line 120 #10

Location: Ancona, Italy

Report compiled by Matthew Sainz, Project Manager at Arrow Monaco 14/12/2022.

Introduction

• Arrow Monaco has been engaged to review the status and quality of build of the new build Custom Line 120´ hull number 10.

• The outfitting is taking place at the Custom Line/Ferretti facilities in Ancona.

• The following report illustrates the status of the build as of the 8th of December 2022 when the vessel was visited.

• The finished vessel will have the following arrangement:

• And the following technical specifications:

01 - Exterior Views

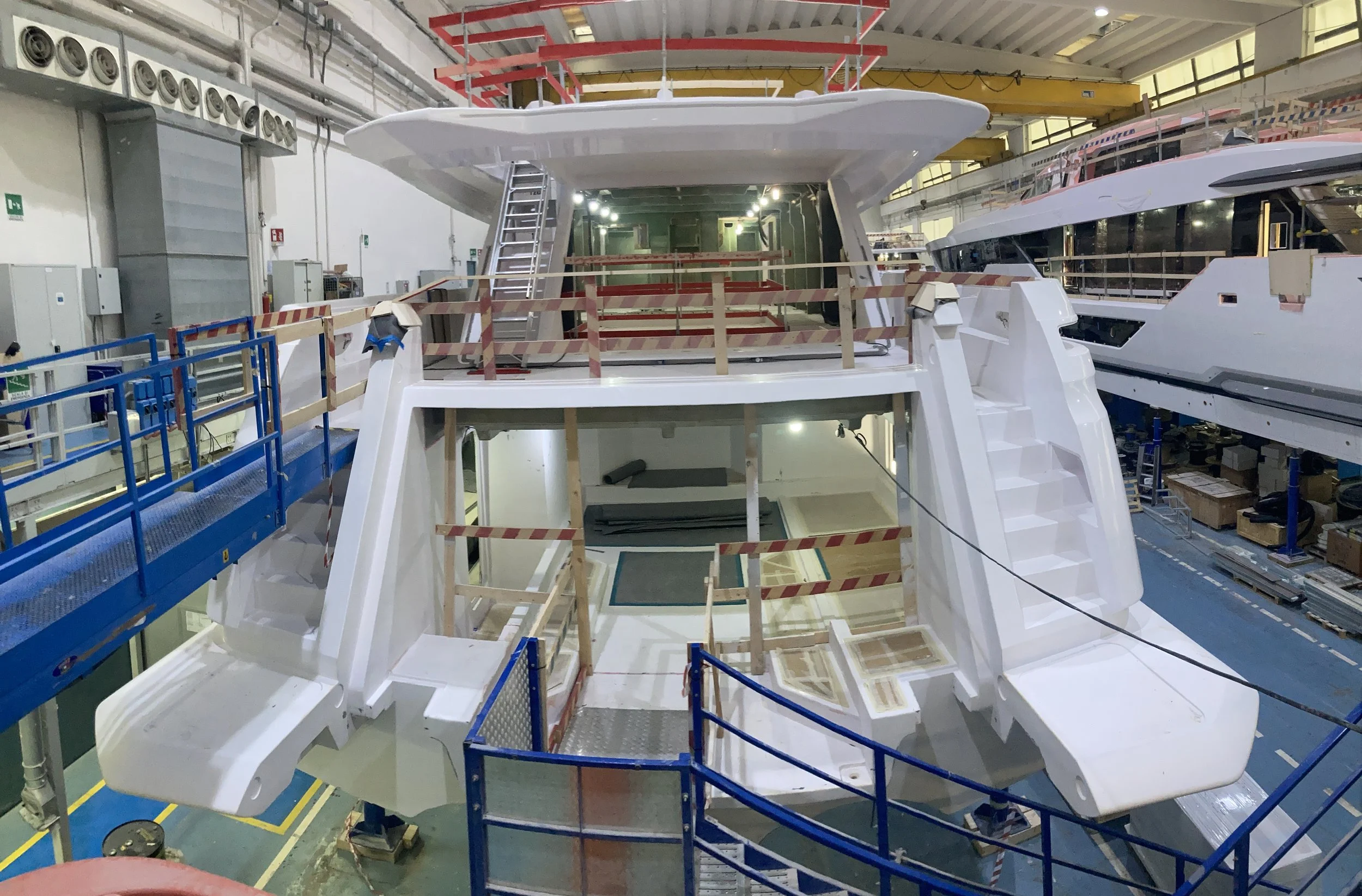

View from aft stbd quarter

• Safety precautions in place (as per safety document present at the yard),

• Electricity, compressed air and extraction pare all present on board,

• Access ladders and passerelles are now on board,

• Transom door is not in place (viewed on yard floor),

• Side bulwarks not in place (both sides),

• Rollbar and mast are missing (not at the yard),

• Gelcoat external surfaces generally in good shiny conditions. Some touch ups required.

• Various components and apparatus found beneath the vessel.

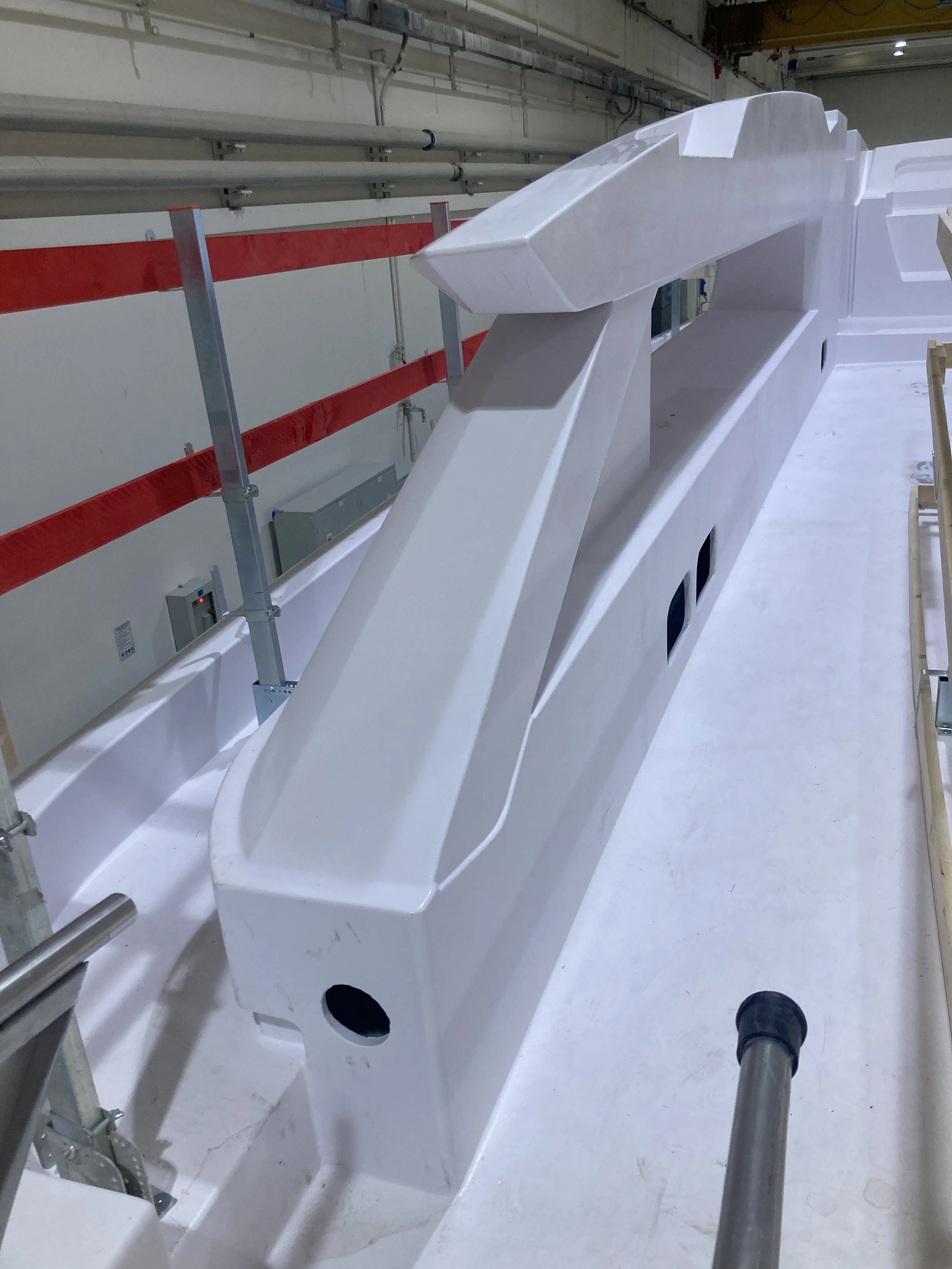

View from yard plateau (aft areas)

• Very little outfitting has taken place to the GRP structure which has recently arrived from the Custom Line subcontractor,

• The subcontractor is a company called B.Metal from Sardinia, and this GRP structure has been transported around to Ancona for outfitting at the Custom Line facilities and covered shed,

• In particular here we can observe the exhaust chamber on the vessel side, which will lead exhaust fumes from main engines through to the aft sections of the vessel. This opening will later be sealed off,

• We can observe no outfitting in terms of shaft line, brackets, rudders yet having taken place to the vessel.

View from bow areas

• Very little outfitting has yet taken place in fwd areas, and in general on the entire underwater hull,

• Anchor housing in fibreglass is in view,

• Fairlead openings ca n be observed, housing and on the bulbous bow,

• Openings for windows and portholes are visible on the vessel sides.

Material on the yard plateau

The following components are located under the vessel and readily available to be installed on board:

• Joinery partitioning components,

• Joinery supporting structure,

• Fibreglass components of the yacht, such as transom door, hatches, and others.

02 - Exterior Decks

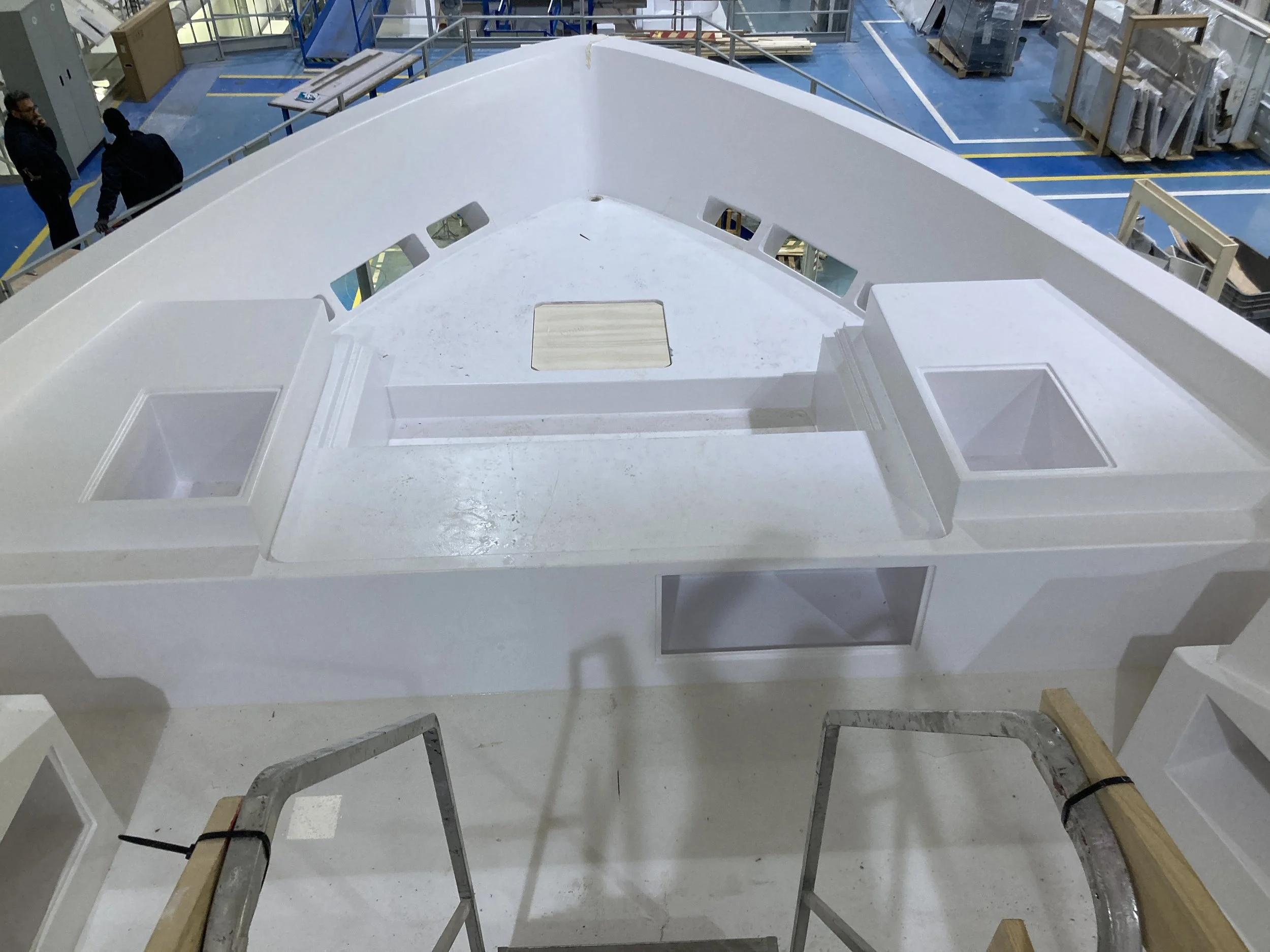

Main deck aft cockpit

• Not much outfitting is yet happening on aft decks as can be seen form these photos,

• Protection bars for open side walks, and staircases for access to various decks have been installed.

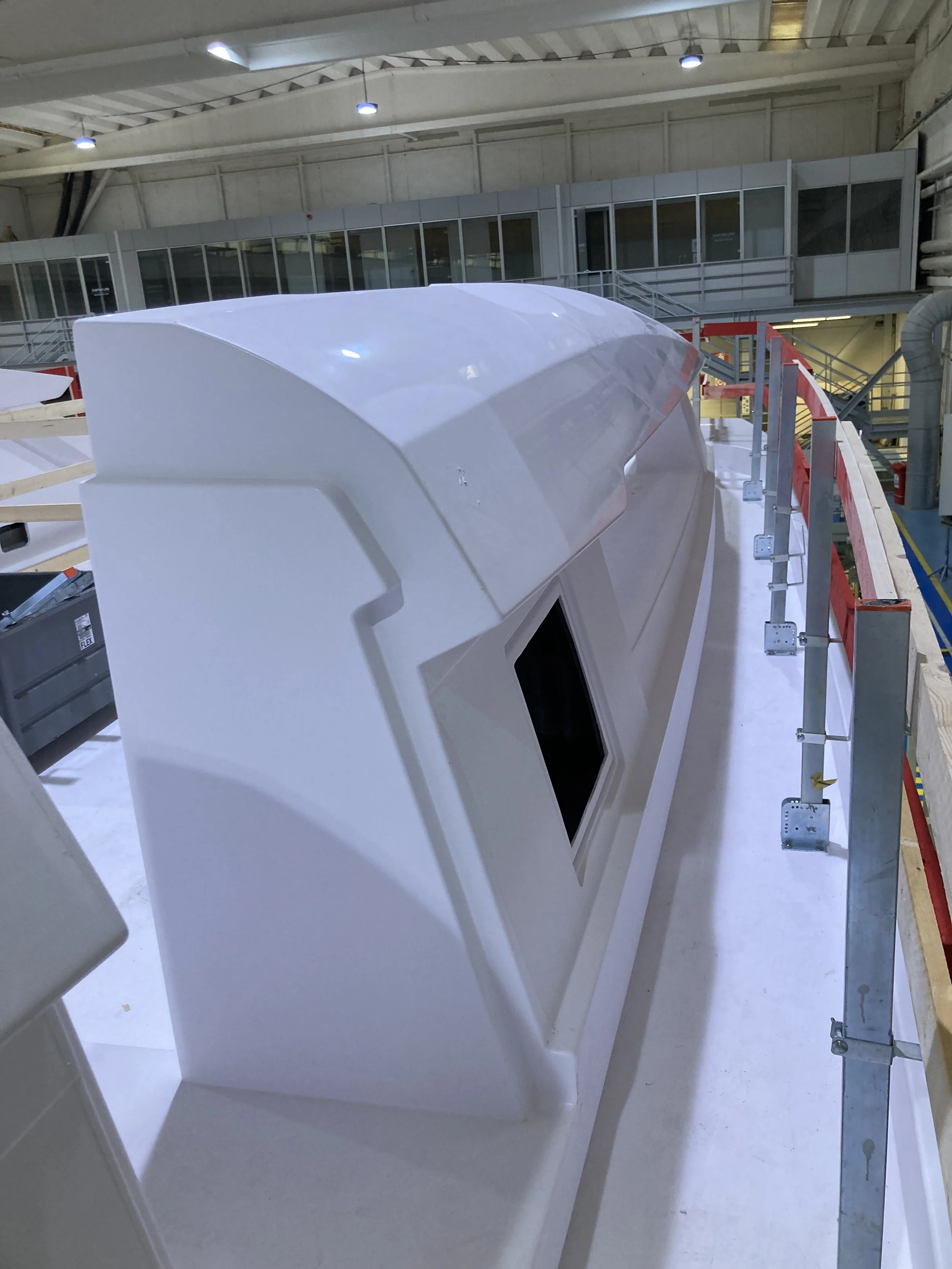

Main deck side corridors

• Not much outfitting is yet happening on these side corridors,

• Protection bars for open side walks and pilot doors are in place.

• The detail of the curved windows on this superstructure side has sprung to our view. We will be monitoring this throughout the build.

Main deck side corridors (pt2)

Filler application on aft sides of superstructure

Side entrance to crew areas on PT side

Access ladder to Engine Room

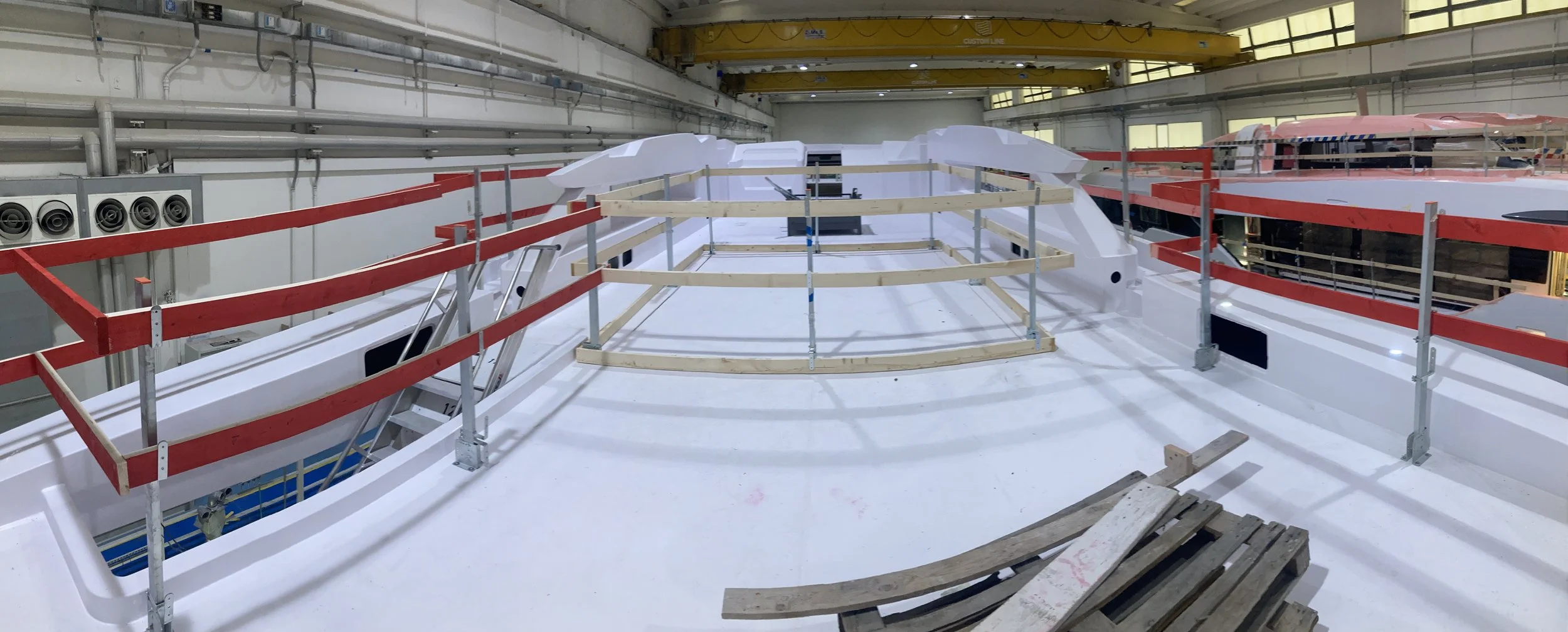

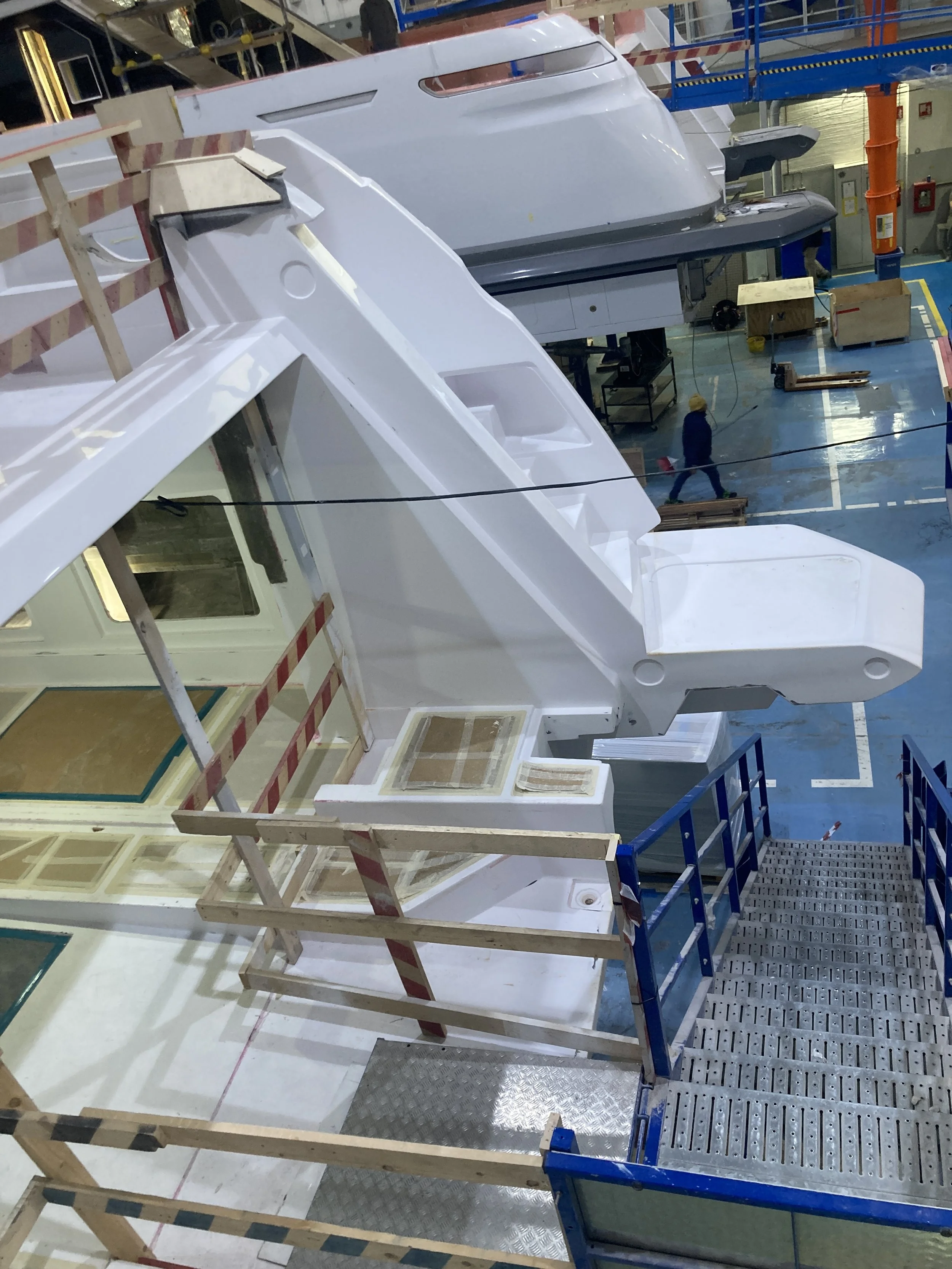

Flybridge

• No significant works can be reported in this area.

Flybridge (pt2)

• Staircase from aft main deck cockpit to the flybridge (temporary staircase),

• Side shapes of superstructure,

• External corridor of flybridge and recess for opening hatch leading to FWD areas,

• FWD areas of the flybridge, including piloting console and access hatch to bridge areas.

Forward deck areas

• No significant works can be reported in this area,

• Shapes for rescue tender or fwd Jetski are visible,

• Shapes for sunbathing areas are visible,

Aft swimming platform and tender garage

• No significant works can be reported in this area.

03 - Interior Areas

Main deck lounge

• Safety & hazard protections have been installed,

• Deck openings for engine room provide ample access for main components to be inserted in the engine room,

• No other significant works can be reported in this area.

Master Cabin

• Partitioning in main GRP bulkheads is in place,

• Modifications will required to fwd areas as per latest contractual GA,

• No other significant works can be reported in this area.

Galley

• Note escape hatch in the photo below,

• Main partitioning in GRP has taken place,

• No other significant works can be reported in this area.

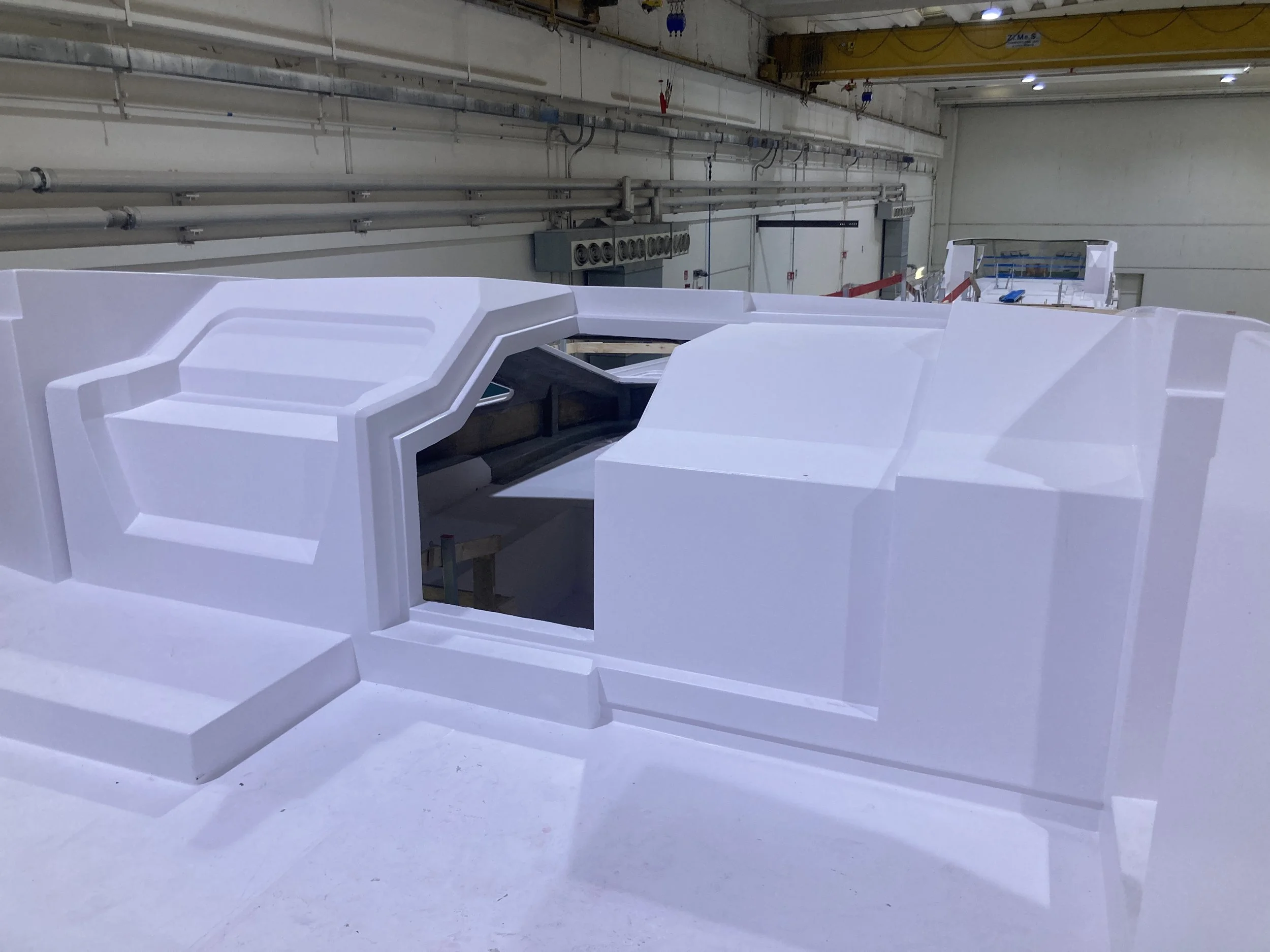

Bridge (Raised Pilot House)

• Access staircase to bridge will be located longitudinally in the photo on the right,

• General spaces and volumes can be viewed below,

• No other significant works can be reported in this area.

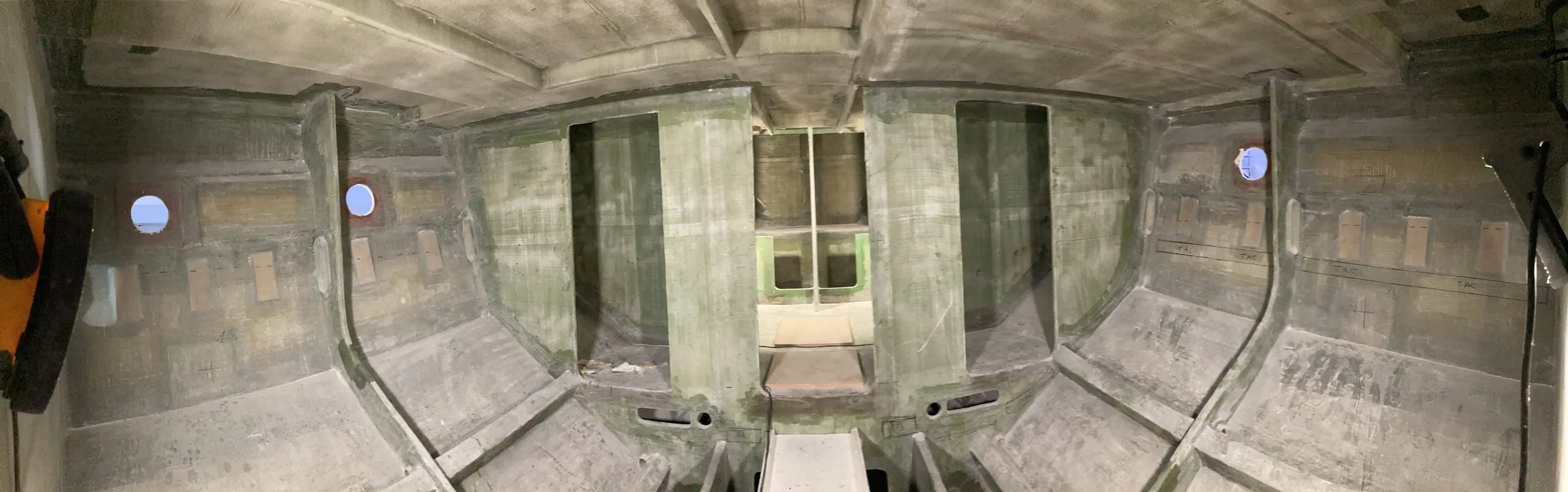

Lower deck guest cabins

Lower deck cabins (pt2)

• Insulation/lagging works have started on board,

• Tanks and tank connections arrive from the subcontractor,

• Tracing for supports of cable trays were being drawn on board.

Lower deck crew areas

• No significant works can be reported in this area.

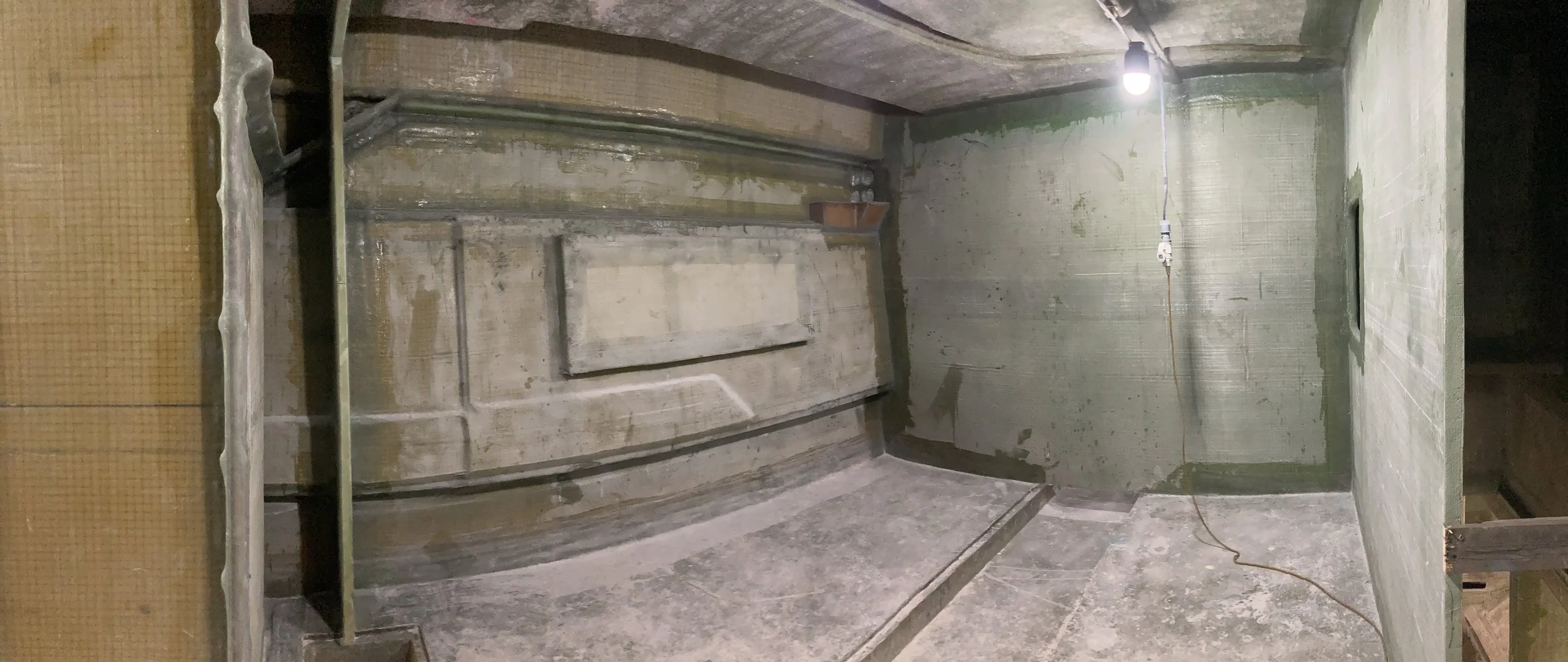

04 - Technical Spaces

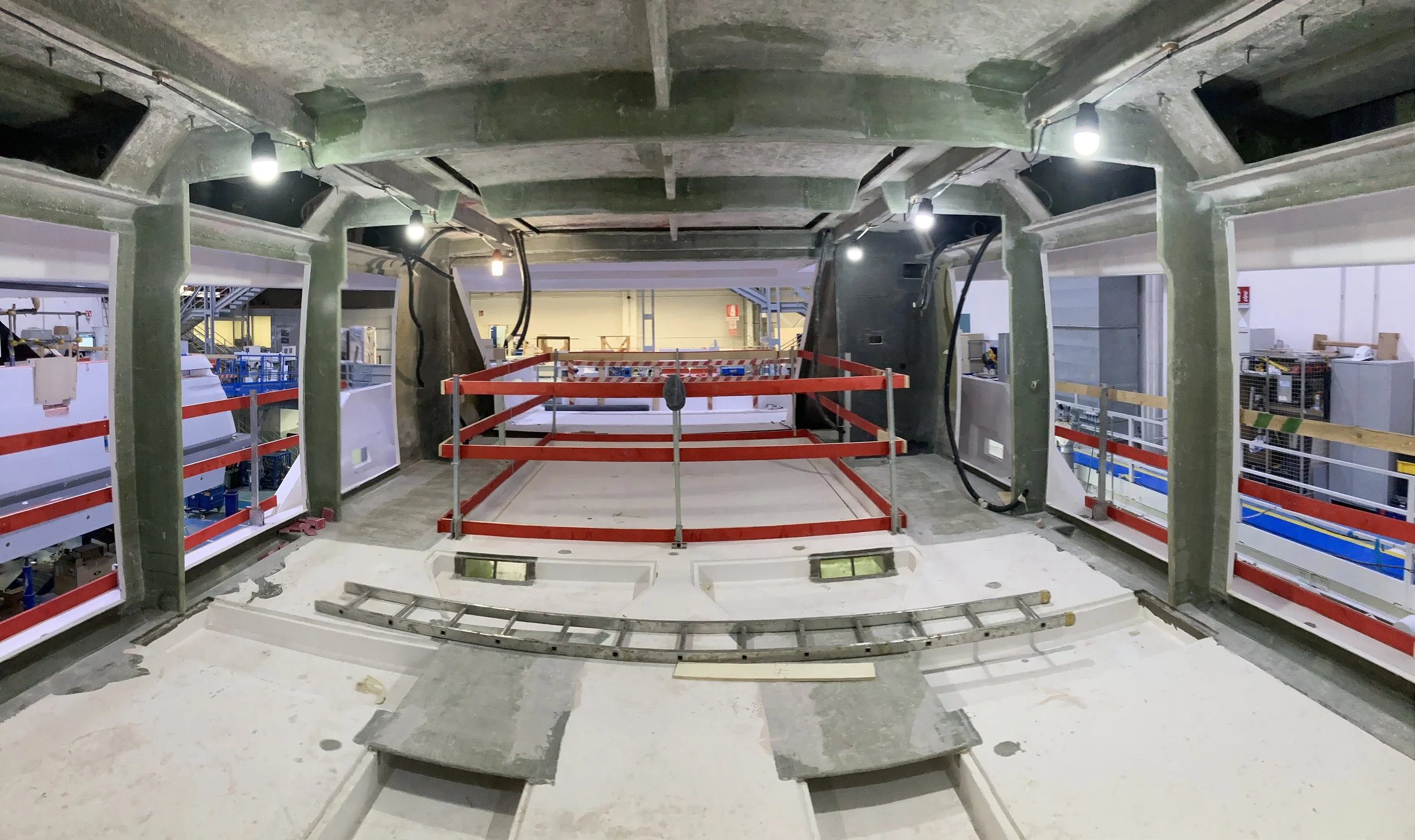

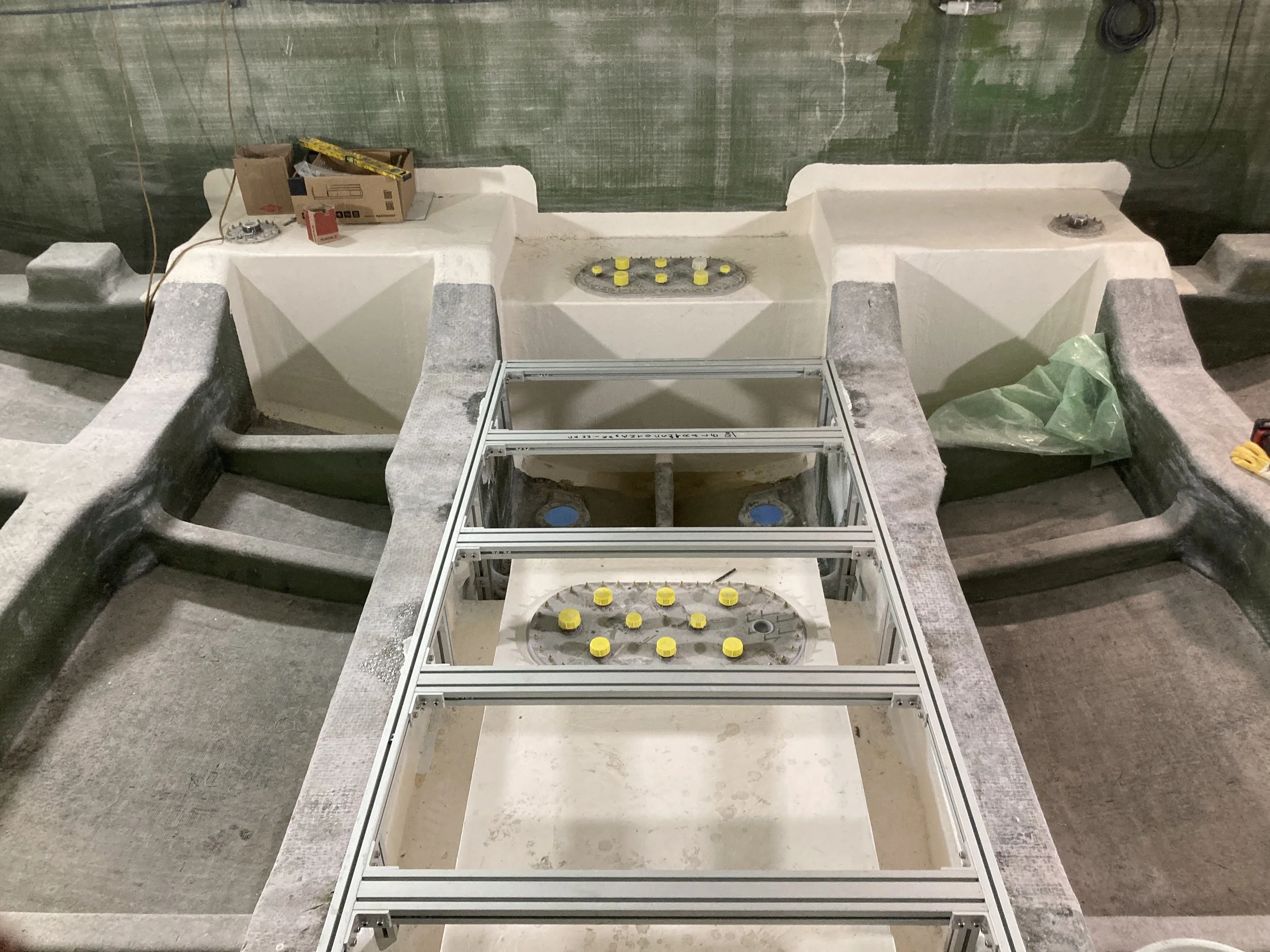

Engine Room

Engine Room (pt2)

• Main engine exhaust cowlings are in place,

• Engine room tanks, with their manholes and connections can be viewed

• Supporting structure for floors and stairs was being installed,

• Openings in fibreglass for seacocks are being undertaken.

Engine Control Room

Main tender Garage

CONCLUSIONS

• The fibreglass shell (hull and superstructure) has just recently arrived from the manufacturing subcontractor, hence there is not much progress on board. The yard has now completed their works to make the shell safe for their works to undertake their jobs on board, and has also provided the necessary tools such as electricity, lighting, compressed air, and ladders/passerelles in order to reach all areas for works,

• There are some materials that have arrived for outfitting, mainly the supporting and partitioning materials from the joiners of the vessel,

• The visual inspection of the fibreglass has been positive, and quality appears good,

• We met with yard representatives and specifically:

Lorenzo Fogar – Project Manager

Luca – 120´ Line Manager

• It has been established that we shall employ Smartsheet for remarks management and control throughout the build,

• Progress of the vessel is being monitored on a fortnight basis,

• Having discussed the program in detail with the PM, at this stage we do believe the vessel can be completed within the time schedule envisaged by the contract.