Progress Report #18 | April 2023

ENGINE ROOM

Emotion battery foundations are in place and welding works continue.

Emotion and Amico generator exhaust supply and installation are underway. SCR installation and lagging works continue.

The hydraulic tank for the Davit crane and mooring capstans has been professionally cleaned and put back into operation.

The perforated sheet insulation is being installed on the final parts of the engine room ready for paint.

ENGINEERING

The new bilge pumping system in the steering flat is now installed and operational on a temporary power supply whilst electrical works continue.

Welding repair on the starboard aft fuel oil tank is now complete. All tanks have now had final inspections, closure, and pressure tests have been completed by Amico.

The steering system is now operational and ready for in-water testing and final service tasks are completed.

Crane works are almost complete, and load and functional tests are to be undertaken in the water.

The anchor winches are now operational, and the anchors and chains have been lifted onboard.

E-MOTION MAIN ENGINE SWAP

The Owner’s team received the unfortunate news from Emotion that there was a service recall on the main propulsion electrical motors supplied by Emotion.

The recall was due to a potential fault in the stator’s electrical windings due to the machine that sets the windings into the stator in the factory being incorrectly set up.

All 4 motors were removed, and new stators were installed and tested in the Emotions workshop before the motors were re-installed in the engine room.

Emotion commissioning works have now begun.

ELECTRICAL

The pumps and consumers in the engine room have been connected to the main switchboard and tested briefly to prove operation before the launch.

The new alarm and monitoring system is now online, the bilge alarms have been tested and operational. The tank calibration will be completed during the first week of May.

Bridge and wing station works continue.

DECK WORKS

The crew and shipyard are busy completing the deck works.

The sundeck is ready for its furniture.

The crew sanded the foredeck where the new storage box is located.

All stainless-steel awning structures are now installed onboard, the canopies are made and ready for installation once Arionas is out of the shipyard environment.

INTERIOR

The crew is busy detailing and completing the inventory in the interior areas.

The chief engineer has begun work on getting the audio-visual systems back online.

The suede headliners have been professionally cleaned.

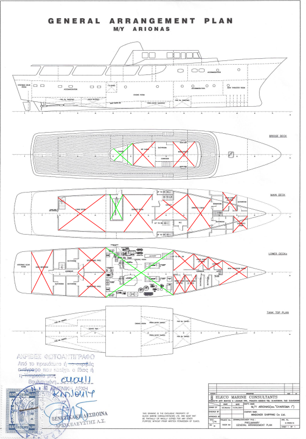

Air quality testing is underway in accommodation and technical spaces as per the general arrangement image. Red areas will all be tested during the month of May.

LAUNCH OF ARIONAS

On the 28th of April Arionas was launched into the slip.

Adjustments were made on the propulsion shaft seals and some fluids were bunkered to achieve 0 degrees list.

Due to some lightship stability concerns, fuel oil bunker is organised for the first week of May which will be followed by the stability and inclining tests to be undertaken by Amico and their naval architects.