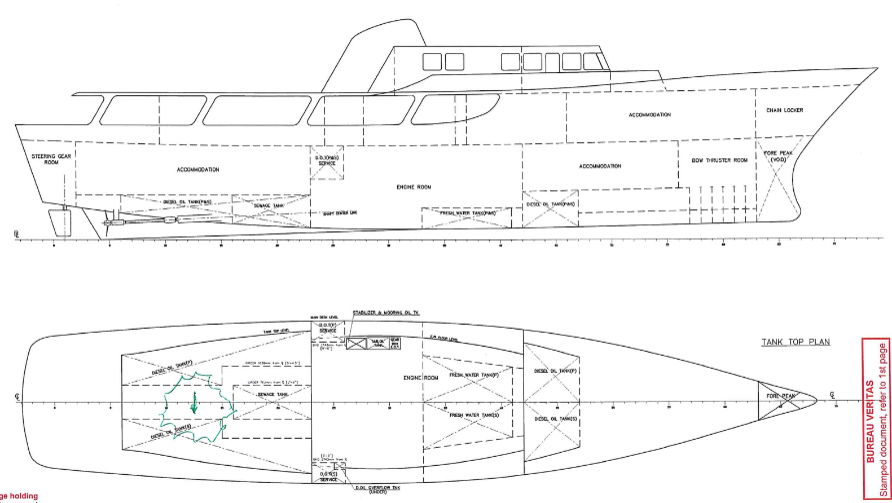

Progress Report #17 | March 2023

PAINT WORKS

The owner's team’s paint survey snag list is almost complete, works are continuing on the minor touch ups around the yacht. There are no further

paint sprays or paint shoots foreseen. Image on the right shows the location of touch up works.

Engine room, other machinery space and bilge paint touch ups are under way by Amico now most of the large works are completed.

Previous and current complaints from the owner's team and crew regarding Amico’s poor housekeeping in machinery spaces continue, and the quality is improving.

E - MOTION

The E motion generator sound enclosures have been delivered to Amico, the E motion technicians have installed the sound enclosures and completed the generators internal electrical wiring and plumbing. There are some further tidying up on the electrical cables inside the sound enclosures that will need to be improved on their next visit. The doors/ panels of the sound enclosures will stay in Amico storage to protect the paint.

SCR exhaust cleaning plant insulation/ lagging manufacturing is completed, the delivery is due to Amico 03rd of April.

The sections of generator exhausts that are part of the E motion supply is planned to begin 06th of April, all sensor connections and auxiliary equipment are ready in Amico.

Emotion have supplied sufficient information on the propulsion batteries for Amico to start planning the works. The drawing for the battery box foundation design has been approved by RINA.

Awaiting more concrete information from E motion on the delivery dates of the propulsion batteries and their final certification.

AMICO ENGINEERING

Electrical boxes for E motion propulsion systems have been re positioned by Amico after Emotions instruction.

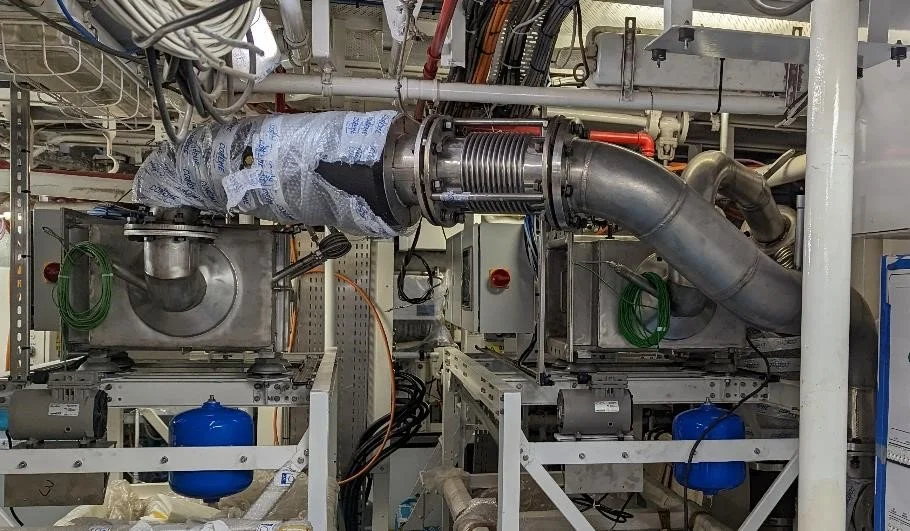

Amico are now completing all the pipework and electrical connections to the 3 generators.

Amico’s generator exhaust works are well underway. The SCR installations continue.

Aluminium floor plate installation first installation is complete. Some alterations and additions are underway.

AMICO ENGINEERING CONTINUED

The seized deck scupper valves have been replaced, the surrounding woodwork will now be re installed.

General service and fire manifolds have been reconditioned, bench tested and re installed onboard ready for the final testing in the water.

Steerage installation is now almost complete. After some small pipework alterations, the system can be filled with oil and tested out of the water prior to the launch. A deep clean is required in this area.

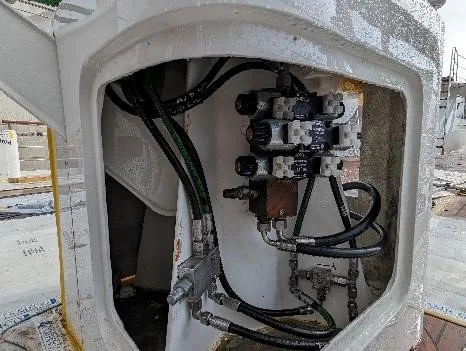

Onboard engineering works on the davit cranes continues, some small leaks have had to be resolved.

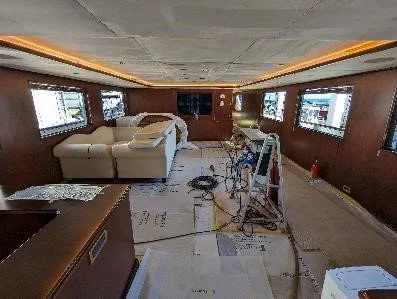

ELECTRICAL

The new shore power cable and its connection have been delivered and installed.

The main switchboard is now live, the chief engineer is now testing and commissioning the ships systems as Amico continue to connect the rest of the electrical consumers. Some labelling mistakes have been noted on the main switch board that will be resolved by Amico.

Power is now live on the interior accommodation spaces and on deck.

Electrical works on the alarm and monitoring system continues.

TANKS

Re coating of the freshwater tanks are complete. Final inspections have been completed by the chief engineer and Arrow Monaco.

Black and grey water tanks are now complete and awaiting their final inspection in the first week of April.

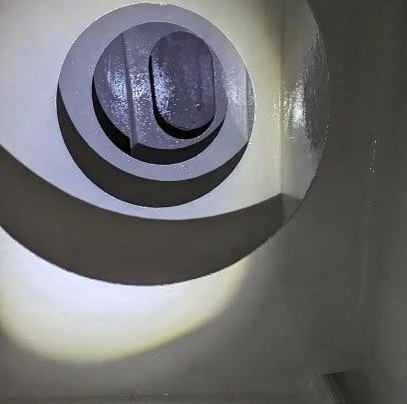

Fuel tank final inspection and pressure tests were undertaken. Unfortunately, a small leak was found on the starboard aft tank as seen on the adjacent image. Minor welding works will soon commence.

It was brought to the attention of Amico that the new urea tank requires an improved bunkering connection. A bunker line will be run local to the other bunker connections.

DECK WORKS

The bridge deck stainless steel works are now completed apart from a few minor polishing details.

The davit box works continue in conjunction with the davit engineering works previously described.

The name lights have been installed by an external contractor organised by the captain. Amico’s quote to conceal and connect the cable works was rejected due to cost. A more cost-effective solution will be found after the refit. The white plastic protection is still on the stainless-steel letter faces.

BRIDGE WINDOWS

The 2 new curved bridge windows have been installed. The interior woodwork has been re installed. Only some small exterior paint touch ups and the final silicone bead need to be completed.

The windows certification has been provided by the shipyard.

INTERIOR

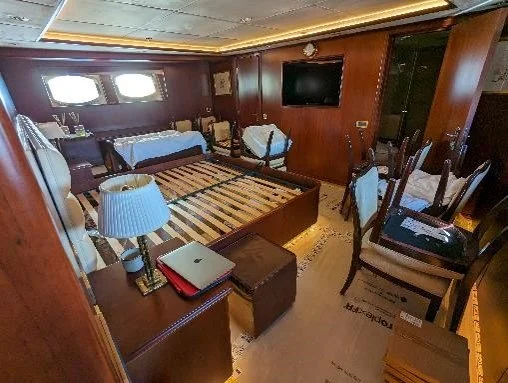

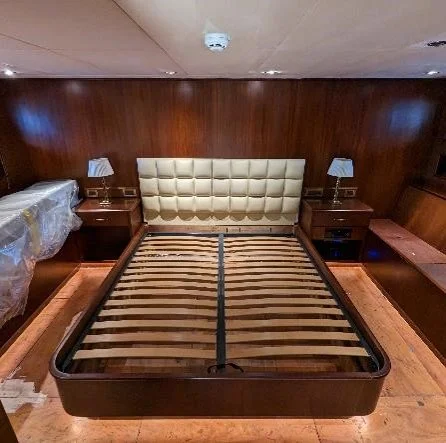

The crew are methodically going through the cabins completing a deep clean, interiorising, re commissioning the domestic electrics and lighting.

Professional carpet, headlining and furnishing cleaning will soon commence.